PFAFF Industriesysteme und Maschinen GmbH Zweigniederlassung KSL

Adresse

PFAFF Industriesysteme und Maschinen GmbH Zweigniederlassung KSL

Bertha-Benz-Straße 4

64625 Bensheim

Germany

Telefon+49 6251 96200

Fax+49 6251 962026

Entdecken Sie mehr von uns

Über uns

PFAFF Industriesysteme und Maschinen GmbH Zweigniederlassung KSL is manufacturer of automated stitching units for technical textiles, tailor made process technology and production automation solutions for the following branches: Automotive Seating, Automotive Interiors, Airbags, Filter Textiles, Home Textiles, Aerospace Preform Technology and Individual Automation Solutions for state of the art production processes.

The range of products is exceedingly multivarious: CNC-controlled sewing systems, multi-needle sewing units, robot systems, glueing- and welding units, as well as complete production lines are to be mentioned. Many of the sophisticated special solutions are innovative unique inventions.

Unsere Produktgruppen

- Sewing Technologies and Materials

- Joining and Fastening Technologies and Materials

Keywords

- Sewing machine

- Automated sewing

- KSL PFAFF

- Roboter stitching

- CNC sewing unit

Unsere Produkte

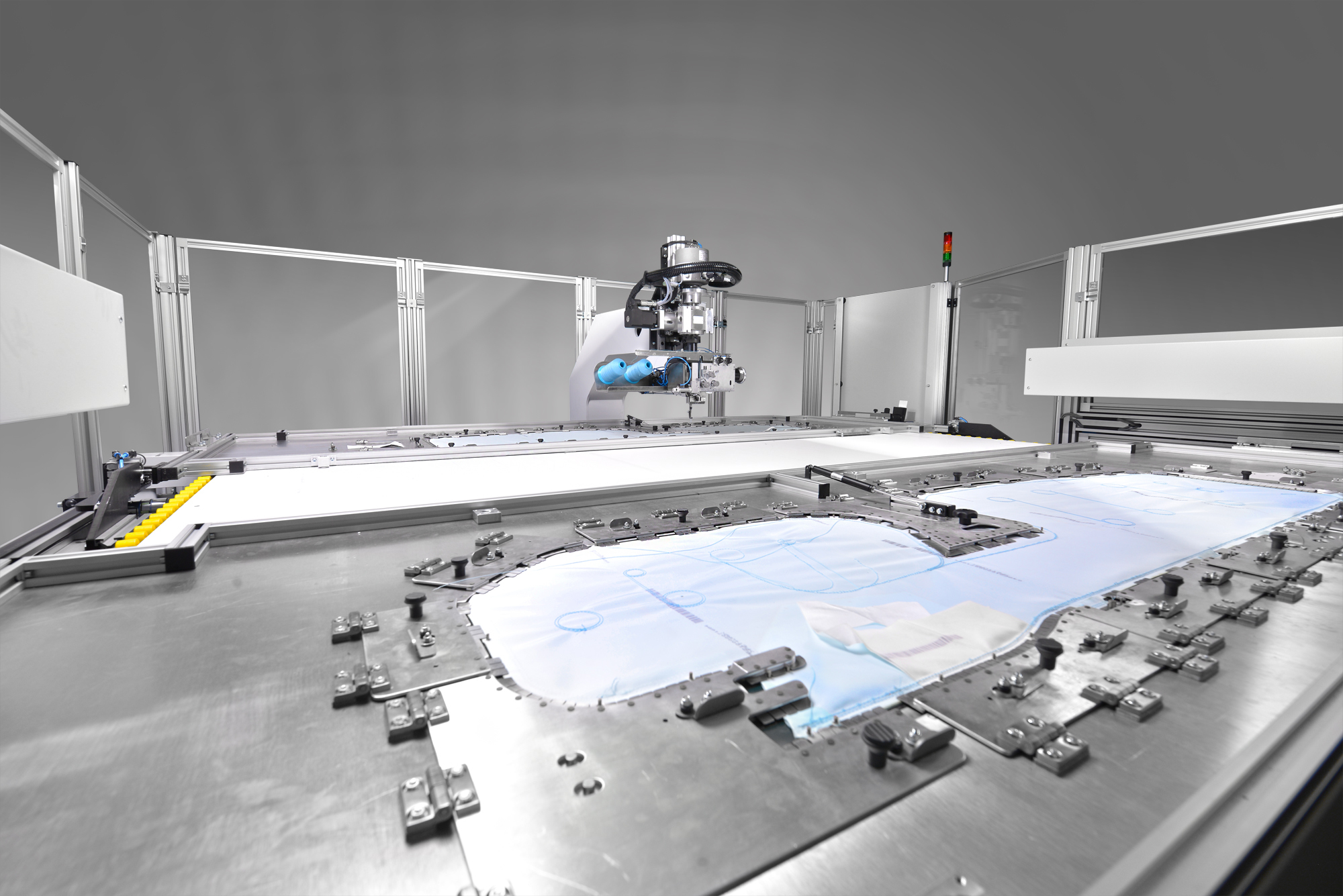

KL 110 CNC Sewing Unit

CNC Sewing Unit with rotating sewing head for servo-motorically controlled sewing of free programmable safety-, functional and decorative seams. Available sewing area from 1,000 x 600 mm up to 3.000 x 1.000 mm.

Features:

- Direct view & access to any seam position due to liftable sewing head

- Reliable thread trimming: Thread trimming concepts (upper and lower thread) for

every application - Switchable, second upper thread tension for perfect adaptation to different material thicknesses/layers during the sewing process

- Intuitive operation with clear real-time seam monitoring on the large 18.5' multi-touch PC panel reduces the training period

- Highest operator safety due to certified safety modules and state-of-the-art light barrier technology (CE compliant)

- Minimized rejects: Real-time thread breakage control with immediate machine stop

- Needle feed can be switched on and off for continuous or intermittent sewing in highest seam quality

- Intelligente Großfeldtechnologie mit max. Rationalisierungsgrad - die Lösung vor eine hocheffiziente Fertigung (z.B. Headbags, Seitenairbags)

- KSL only: Vollautomatisches Nähguthalter-Wechselsystem komplett in Maschine integriert für eine vollüberlappte Arbeitsweise (=extrem kompakter Footprint)

- KSL only: Im Einlegebereich eingelassene Glasplatte (von unten beleuchtet) zur visuellen Kontrolle des Nahtverlaufs, z. B. bei Silikonapplikationen (Option)

- Messsystem an Y-Achse für eine prozesssichere und wiederholgenaue Positionierung und Bewegung des Nähguthalters; prädestiniert für 1- und 2-Nadel-Applikationen im Seating- & Interior-Bereich

KL 311 CNC Sewing Unit

CNC Sewing Unit with stationary or rotating head sewing machine for servo controlled continuous or intermittent free programmable sewing of high quality security-, functional- and decorative seams. Rotating head version especially for highest seam quality with demanding tangential multi-directional sewing operations.

Features:

- Direct view & access to any seam position due to liftable sewing head

- Reliable thread trimming: Thread trimming concepts (upper and lower thread) for

every application - Switchable, second upper thread tension for perfect adaptation to different material thicknesses/layers during the sewing process

- Intuitive operation with clear real-time seam monitoring on the large 18.5' multi-touch PC panel reduces the training period

- Highest operator safety due to certified safety modules and state-of-the-art light barrier technology (CE compliant)

- Minimized rejects: Real-time thread breakage control with immediate machine stop

- Needle feed can be switched on and off for continuous or intermittent sewing in highest seam quality

- Perfect price/performance ratio for complex sewing operations and special applications up to 1,500 x 1,000 mm

- Template movement in Y direction and sewing head movement in X direction are predestined for highly decorative seams (vehicle seats or interior door panels, but also special applications, e.g. cable laying for heating elements)

- Low space requirement: Template movement in Y direction ensures working with large templates on a small footprint

KL 500 Robot Sewing Unit

Robot supported sewing process for manufacture of application specific decorative seams for automotive interiors.

Features

- Industrial robot with additional, fully synchronous sewing axes

- Individual sewing head design (clearance and height of column) for processing of most varied dash board geometries

- Rotary indexing table for overlapped procedure and highly efficient cell utilization

- Tool changer for fully automatic exchange of various sewing heads

- 3D-component support for material specific, reproducible positioning of ambitious interior components