Die Aussteller & Produkte der Texprocess 2026 finden Sie ab Mitte Januar 2026 hier.

Technologietransferzentrum Main- Spessart

Technologietransferzentrum Main- Spessart

Spessartstraße 1b

97828 Marktheidenfeld

Germany

Telefon+49 9721 9408572

Über uns

The Technology Transfer Center Main-Spessart (TTZ-MSP) brings the know-how of the university of applied sciences directly into your company. We support you throughout the entire process chain of digital, additive manufacturing – from the initial idea to series production.

Another highlight is our expertise in process monitoring. Our experts have developed a thermography method for measuring absolute temperatures during the solidification of metal components. For this purpose, the field of view of an infrared camera is guided by a second scan head at a defined distance from the laser–material interaction zone. In the testing setup for "Synchronized Path Infrared Thermography" (SPIT), this enables analysis of the cooling behavior in laser-based powder bed melting processes below the melting temperature. In addition, defects can be detected based on the data, as documented in several of our peer-reviewed publications.

We also offer a broad portfolio of characterization methods. These include comprehensive laser beam characterization, powder characterization using digital image analysis and powder rheology, 3D metrology including reverse engineering, as well as component and material analysis using a fully equipped metallography lab, high-resolution digital microscope, and CT. In addition, we provide various mechanical characterization methods (hardness, tensile/compressive strength, and fatigue strength).

To round off our offering, we provide consulting throughout the entire digital process chain – from the initial design to the finished component.

Unsere Produktgruppen

- Software and digitalization solutions

- Industrial design

- Engineering and part design

- Quality management / metrology

- Process monitoring

Keywords

- Prototypen

- Design

- Produktentwicklung

- Multi-Material

- Lasercharakterisierung

Unsere Produkte

Research Test Bench for Technology Development

The TTZ-MSP has a modern research test bench for process monitoring in PBF-LB via SPIT. an acronym for "Synchronized Path Infrared Thermography". SPIT is a cutting-edge method for process monitoring in additive manufacturing. This innovative system utilizes two synchronized galvanometer scanners to capture thermal information during the PBF-LB/M process. One scanner steers the laser beam over the build platform, while the second precisely guides the field of view of an IR camera. This setup enables high-resolution, high-speed, and reliable observation of the melt pool and the surrounding heat-affected zone. This technology provides valuable process data, which allows for improved quality assurance and drastically reduces the effort required for downstream quality control.

Furthermore, a test bench for measuring laser sources using high-end PRIMES devices is available. The laser beam can be measured with Power Cubes, the Focus Monitor+, the Micro Spot Monitor, and the Scan Field Monitor. We are also happy to advise you on any questions you may have regarding laser measurement.

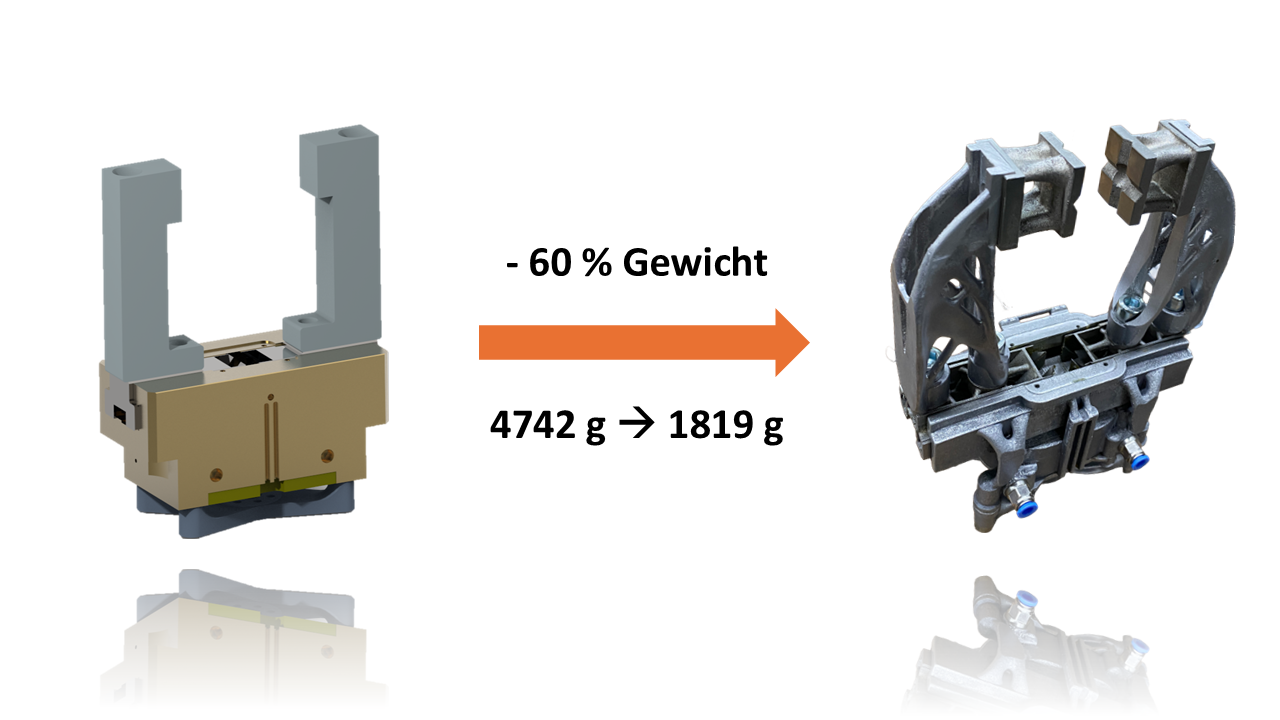

Design for AM

At TTZ-MSP, we cover the entire additive manufacturing (AM) process chain. Starting with material selection and determining the optimal manufacturing process, all the way to design for AM including topology optimization and manufacturing of a demonstrator. Our experts will be happy to help you make the most of the possibilities offered by additive manufacturing for your product or component.

The design for AM is shown using the example of a gripper, which achieved a weight reduction of 60%.

Test of Additive Manufactured Samples and Parts

We offer a wide range of testing options for specimens:

- Powder analysis Particle size & shape | Anton Paar Litesizer 500 DIA

- Powder analysis Flow properties | Micormeritics FT4

- Static strength (tension/compression) up to 250°C | Zwick&Roell LTM10

- Fatigue strength (tension/compression) up to 250°C | Zwick&Roell LTM10

- Computed tomography (defects & dimensional accuracy) | Wenzel exaCT L 225 kV

- Metallography & microscopy | Keyence VHX-X1

- 3D measurement with reverse engineering | Shining 3D SP V2 & Keyence VL-700

- Heat treatment optional with protective gas up to 850°C | Nabertherm NA60/85

- Laser diagnostic | PRIMES Cube, CubeM, Focus Monitor+, Micro Spot Monitor, Scan Field Monitor

Our range of services also includes testing prototypes, as you can see in our LinkedIn series #GripperThursday in collaboration with EOS and Siemens.