The exhibitors & products at Texprocess 2026 will be available here from mid-January 2026.

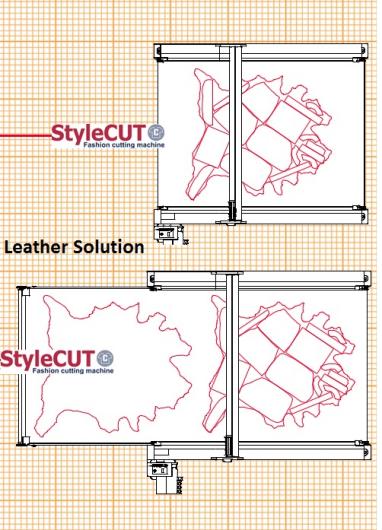

StyleCUT Leather cutting solution: RHINO interactive and automatic optimization of leather surfaces

StyleCUT Leather cutting solution: RHINO interactive and automatic optimization of leather surfaces

Description

StyleCUT Leather Solution

The leather applications; A modern production system, however, also includes features such as standardization of hardware and software, scalability, connectivity, a database, statistics and, last but not least, low operating costs. All of this is offered by the RHINO leather cutting system.

The RHINO leather cutting system can be applied and configured for prototype-building, for small series and for mass production in the automotive-, aircraft-, upholstery- and related industries.

The system can be configured according to the following process steps: Job management, capture hide contour and quality areas (1.), nesting the templates (2.), automatic cutting (3.) and sorting (4,).

The smallest configuration (prototyping) consists of a cutting table sized to take up one or more hides (depending on area). All the process steps mentioned above are carried out in sequence. The system can be delivered with different table configuration due to customer productivity need.

The processes

- Hide capture: The hide laid out on the table is scanned with a high resolution camera. This captures the hide contours, the hide structure and all indicated quality symbols for the definition of usable areas (4 Q-zones). Along with the evaluation of the hide illustration, the system stores all the relevant hide parameters in the integrated data base.

- Nesting process; The database-supported job management delivers the amount of templates for automatic nesting onto the current hide. The process time of the automatic nesting can be controlled automatically, depending on the cutting time. With particularly sensitive products, the user can either nest via option “beamer nesting” (with multi-function mouse) or place selected cut parts on the screen and then leave optimisation of the remaining usable area to the automatic function.

- Cutting; In the three-table segment configured for high capacities, there are constantly three hides in the overall process (capture, cut, sort), of which one is always cut. Minus the short conveying times, the cutter, as the pacesetter of the system, with a capacity utilisation of over 90 percent, ensures virtually non-stop production.

- Sorting of the finished cuts; As soon as the cutter has conveyed the contents of its cutting window to the third table segment, the sorting process can begin. The RHINO system offers a beamer-supported sorting aid as an option.

Disclaimer: The performance characteristics specified herein depend on the individual system usage and on the maintenance prescribed by the manufacturer. The technical content listed in the description may vary in the course of the further development of the system and is therefore not binding.