The exhibitors & products at Texprocess 2026 will be available here from mid-January 2026.

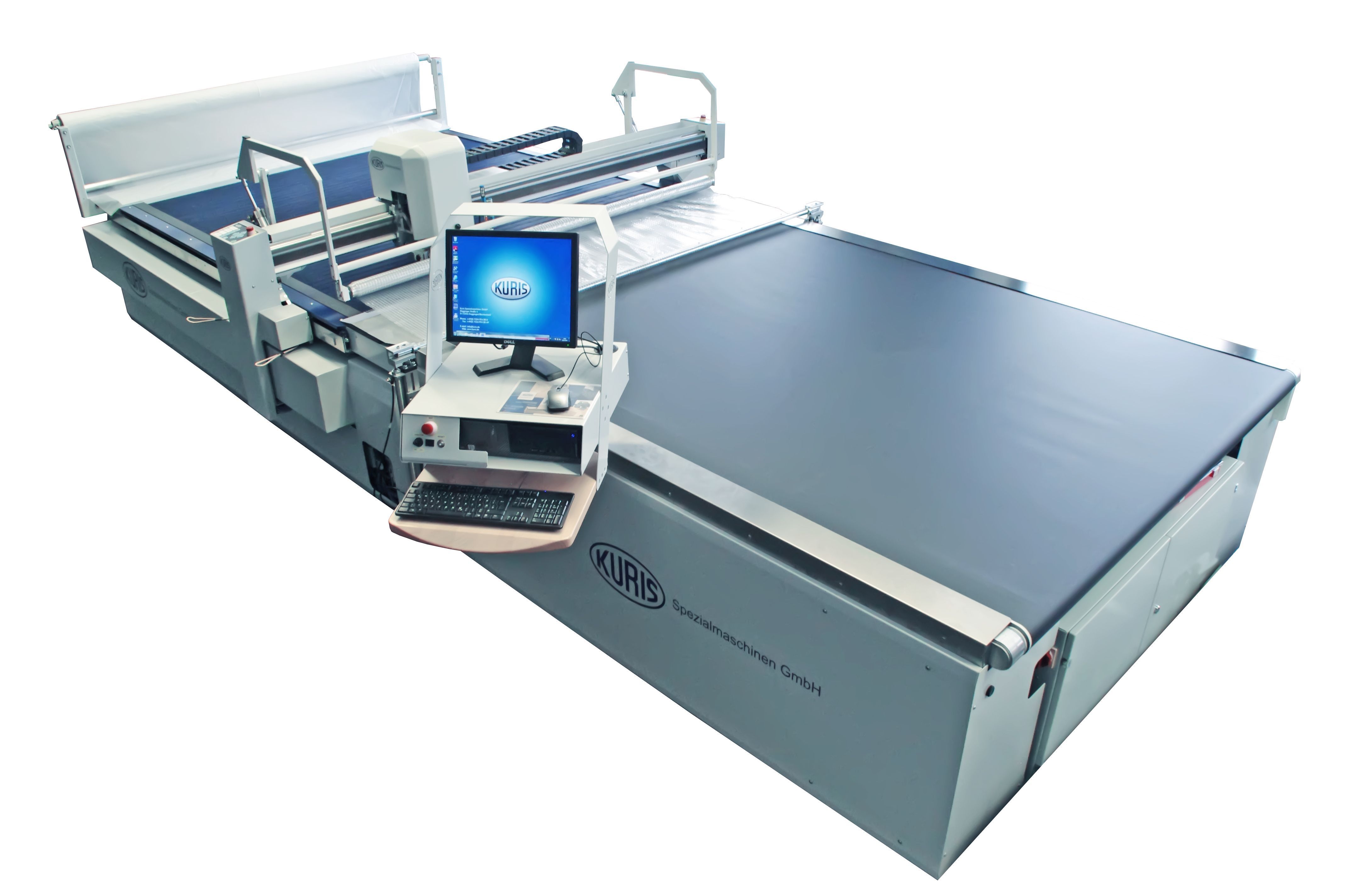

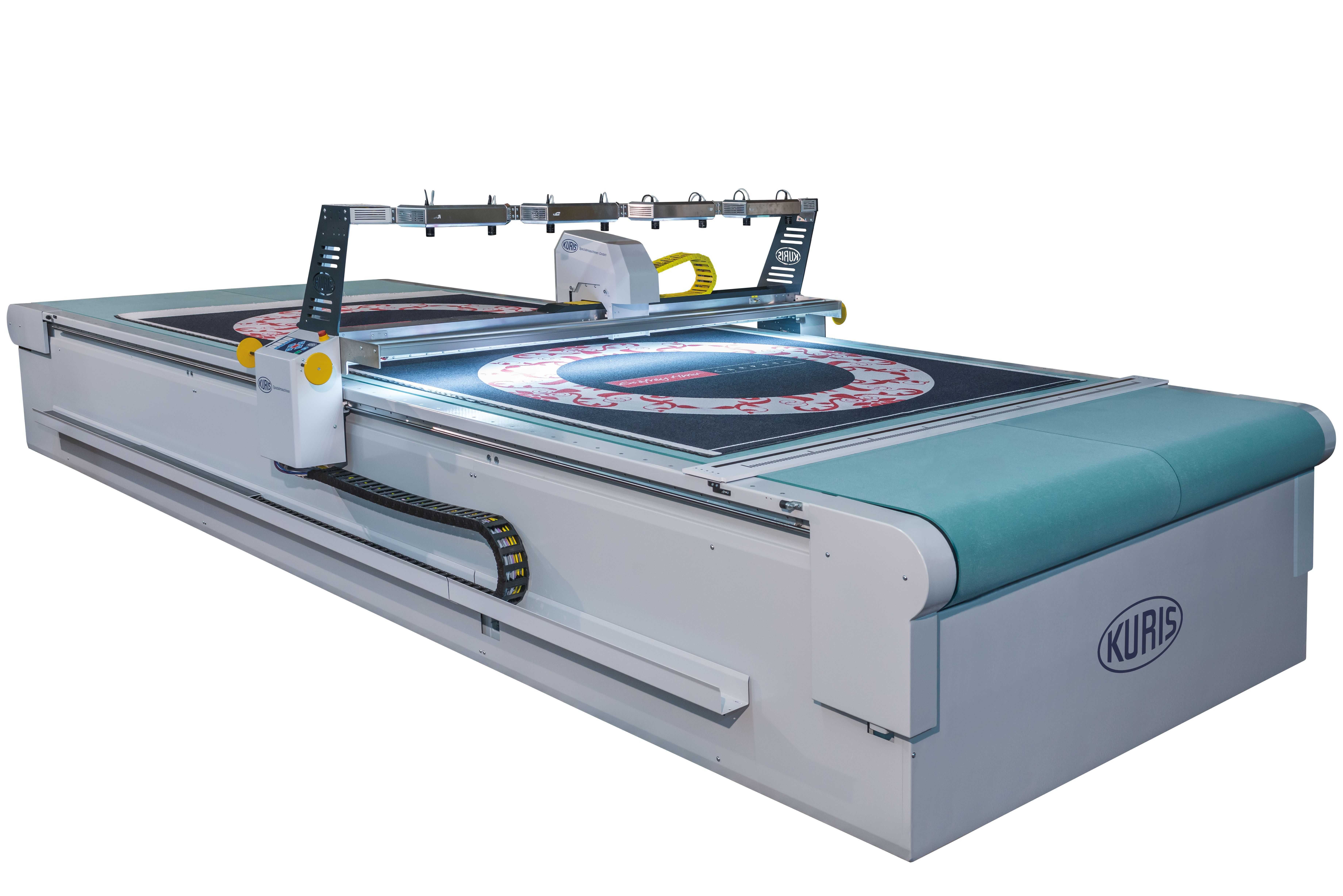

spreading-machine

Description

The Kuris Shuttle spreading machine suits perfectly for critical, smooth materials and/or even badly rolled material bars with different surfaces. The new deviating roller system of the driven cradle or material bar ensures an excellent quality in spreading. Even through fully automatic spreading of tension-sensitive materials excellent spreading results will be achieved.

The precise and regulated prefeed material roll will exactly suit the required spreading speed.

The semi of fully automatic unthreading/threading of the fabric will reduce essentially the set-up times. Many steps to be taken for the spreading with different positioning and cutting points, quantity of layers, zig-zag spreading programmes as well as numerous custom-made parameters can be individually programmed.

Applications:

- Clothing industry

- Automotive industry

- Aviation and Space industry

- Furniture industry

- Construction

- Boat industry

- Railway industry

Advantages at a glance:

- cradle with fully automated lifting for ergonomic loading process

- a new idler-pulley system for the continuous running of the conceyor belt (option)

- user-friendly machine control

- graphical user interface

- easy to use

- software update possible even after several years of use

- programming possibilities for many spreading steps

- silicon coated drive wheel

- photocell electric for the examination of the edge control even for difficult materials

- different cutting units simply to be mounted

- dynamic speed control

- robust control cabinet-housing with power coating surface

Options:

- fabric edge-blowing feature against curling effect

- turnable

- driven rolling bar for tension-free spreading

- Zack-cutting unit

- Zig-Zag spreading with catcher system

- Cradle execution

- Travel-on platform

- Anti-static bar