Merrow Superior, LLC

THE MERROW EDGEHOG

Explore product

THE MERROW EDGEHOG

Explore product

THE MERROW EDGEHOG

Explore productAddress

Merrow Superior, LLC

502 Bedford St

Fall River Massachusetts 02720

Vereinigte Staaten

Telephone+1 212-691-5900

Fax+1 508-689-4095

Discover more from us

About us

The Merrow Group, a leading company with diversified manufacturing interests, all headquartered on our six-acre Merrow campus in downtown Fall River, MA. Our major divisions include Manufacturing, Machines, Wholesale parts and equipment for the sewing industry and Sustainable Medical products.

With a rich history dating back to the late 1883, The Merrow Machine Company is owned and operated by Owen and Charlie Merrow, the 8th generation of the Merrow family. We take pride in producing some of the world's finest industrial sewing machines. Our machines have been trusted by various industries, ranging from footwear and upholstery to canvas and military wear. Known for their sturdiness and long-lasting performance, Merrow machines are built to last and ensure our customers' manufacturing success.

To further enhance our offerings, we acquired Superior Sewing in 2019, the largest wholesale distributor of sewing machine parts. This addition expanded our line of Merrow parts, supplies, and peripheral devices, reaffirming our commitment to providing comprehensive solutions to our customers. In 2022, we also gained the distribution rights for the Orange needle, further diversifying our product lines and brand affiliations.

We are now proud to introduce our latest additions, including the Edge Hog, the world's first automated emblem maker and being named the official distributor of the world renown Cometa sewing machine in the Western Hemisphere. These cutting-edge additions demonstrate our ongoing commitment to staying at the forefront of technological advancements to better serve our valued customers.

We look forward to partnering with you and ensuring your success in the world of manufacturing.

Our product groups

- Sewing Technologies and Materials

Keywords

- sewing machines

- parts and supplies

- wholesale

- Merrow

- Superior

Our Products

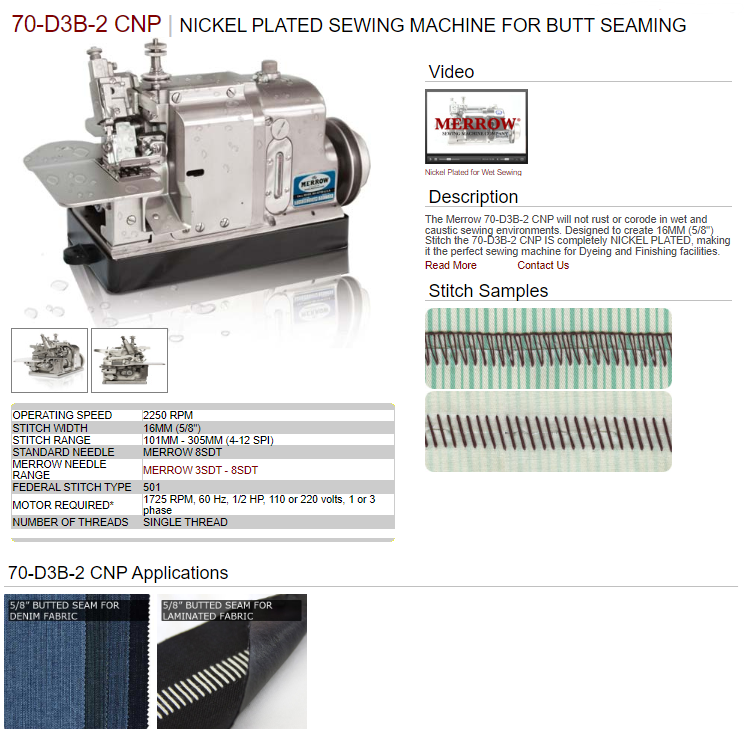

The Merrow 70-D3B-2 CNP

The Advantage of the 70-D3B-2 CNP

The Merrow 70-D3B-2 CNP industrial sewing machine is designed to sew in harsh environments. It produces the same flat butted seam that has made the 70-D3B-2 the industry standard for end-to-end seaming, but has been chemically nickel plated (CNP) to allow for sewing on wet fabric. Chemically adhering the nickel to the machine offers the utmost protection from corrosion, and like all Merrow machines the 70-D3B-2 CNP is hand assembled with high quality steel parts, ensuring a perfect butted seam even after years of use.

The 70-D3B-2 CNP can be configured to produce a butted, gap, or overlap seam to achieve optimum results, according to the fabrics and manufacturing processes used.

WHY it's better

The 70-D3B-2 CNP Will not Rust - it is Designed for WET environments. The quality of the nickel plated sewing machine is unparalleled in the industry. No other manufacturer provides as well designed and protected a sewing machine as Merrow. The 70-D3B-2 CNP will stand up to Bleaching, Mercerising, Dyeing etc., and in these environments will often provide dozens of years of uninterrupted service

HOW it's better

Nickel Plating. Merrow uses a proprietary method of nickel plating that covers 100% of the sewing machine. The process doesn't chip and prevents oxidation. Parts are specially manufactured for the CNP machine The parts for a Merrow Nickel Plated machine are all specially manufactured to accommodate the proprietary nickel coating we apply. This ensures that the machine will operate at the same speed as the 70-D3B-2

WHERE it's used

The 70-D3B-2 CNP is often used in wet environments; in Dyeing and Finishing plants, specifically in the following operations: bleaching, dying, Mercerising, Washing, Printing operations . It operates on a table or a railway - and is often paired with Merrow's Air Motor .

The 70-D3B-2 CNP is one of more than 350 variations of the Merrow 70-D3B-2

learn more about the 70-D3B-2

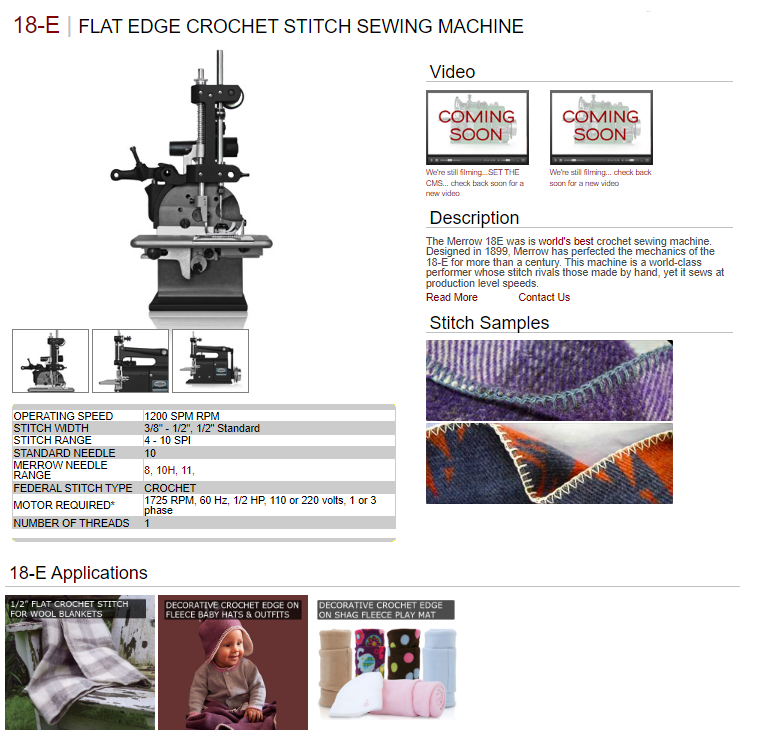

The Merrow 18E

The Advantage of the 18-E

The Merrow 18E sews a 3/8" - 1/2" flat crochet stitch on blanket and garment edges. It runs at speeds up to 1400 SPM, yet produces a stitch that rivals any sewn by hand in craftsmanship and uniformity. The 18E is a single needle, single thread machine that sews at a standard 4 SPI, but can be adjusted to sew at a remarkable 10 SPI.

WHY it's better

The 18E runs at nearly 1500 stitches per minute, yet sews a stitch of such distinction that it is sure to compliment even the highest quality blankets and garments. Like all Merrow machines, the 18E is designed and built to last for decades, providing operators with thousands of hours of uninterrupted service.

HOW it's better

The 18E is hand-built, and this craftsmanship shows in its stitch. Using Merrow's the latch hook system pioneered and perfected by Merrow, the 18E creates a flat crochet that replicates the hand sewn stitch.

WHERE it's used

The flagship crochet sewing machine from Merrow is used in large production facilities, small businesses and homes. It is often used to edge blankets, pillows, shawls, hats and mittens. With thousands of standard 'whip stitch' applications, the 18E is the machine to use for small to medium production of these applications.

MB-4DFO-Production-Series

The MB-4DFO 2.0 is the only machine to sew Merrow's ActiveSeam® for base layer activewear. It has the versatility to all three unique ActiveSeam™ stitches and can be configured for two or three thread sewing.

WHY it's better

NEW!!! The MB-4DFO 2.0 sews all three variations of the ActiveSeam stitch. It was specifically developed to sew on base layer garments and the ActiveSeam family of stitches are flat, comfortable, and stretchable stitches that replace traditional flatlock seams. The MB-4DFO 2.0 stitch width can be varied from 3/32" to 5/32" according to material properties and/or application requirements and is custom configured to sew specifically using customers' unique material and thread. Tension settings, eccentrics, and cutter placement are all adjusted to ensure that the customer receives a unique version of the ActiveSeam that is specific to their garment and application.

HOW it's better

NEW!!! The NEW MB-4DFO 2.0 utilizes Merrow's unique barrel cam architecture and curved needles to sew more precisely and consistently than other sewing machines. Because the MB-4DFO sews with two needles, it has the versatility to sew three different stitches and with either two or three threads. The MB-4DFO 2.0 is hand-built in the USA and all parts are integrally designed to ensure both stitch superiority and machine durability.

WHERE it's used

NEW!!! The Merrow MB-4DFO 2.0 is used in cut and sew factories the world over to sew the ActiveSeam on technical fabrics and base layer garments. Merrow's worldwide network of authorized agents are trained in all aspects MB-4DFO 2.0 service and installation.

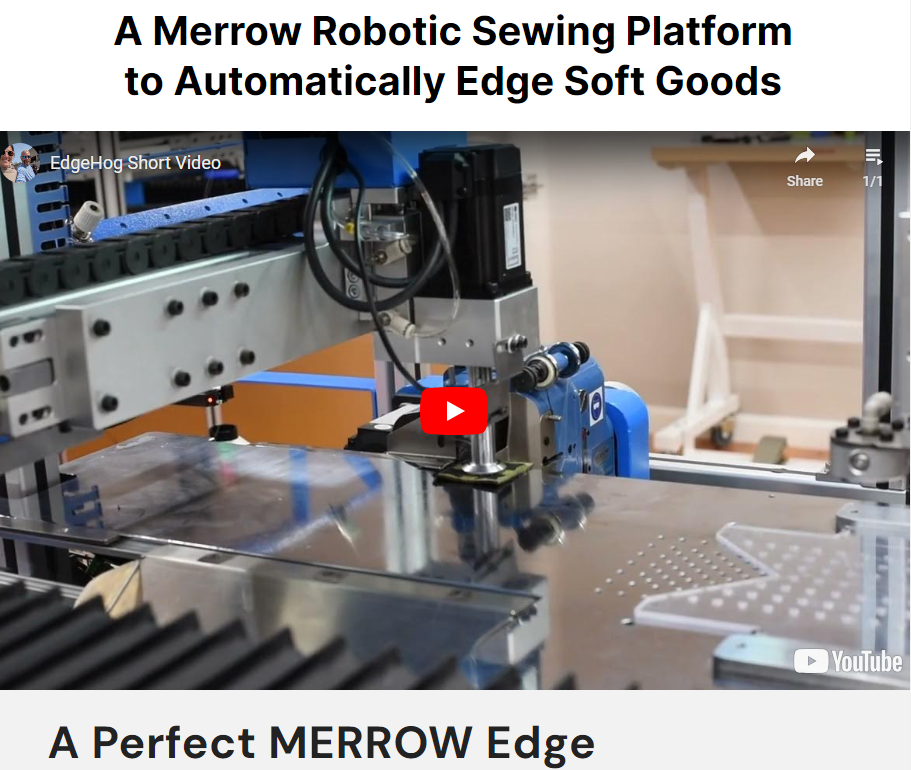

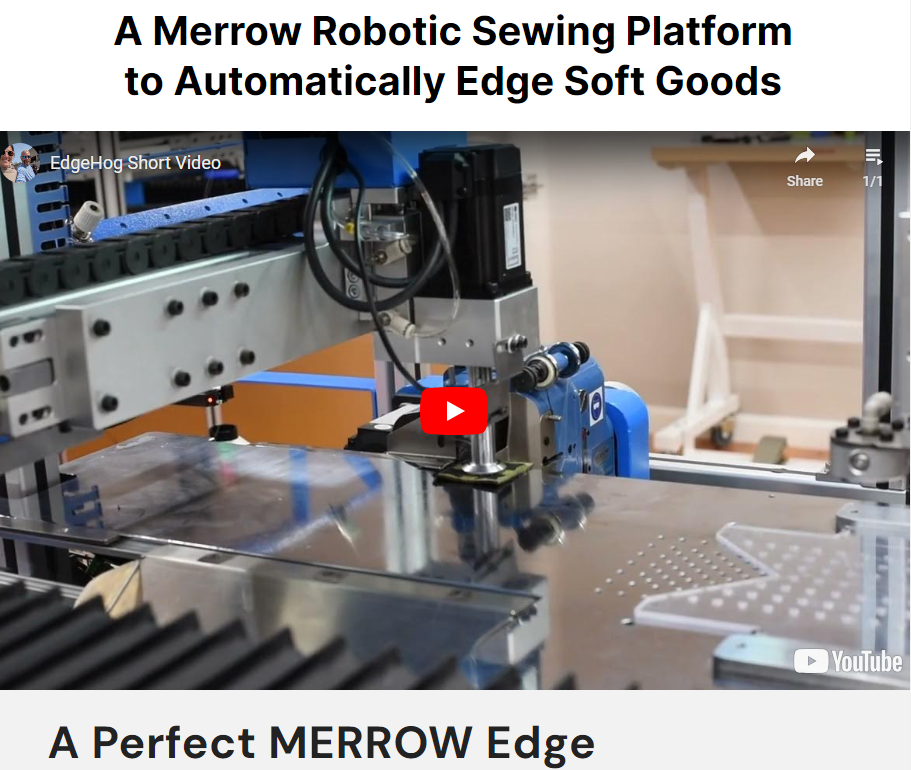

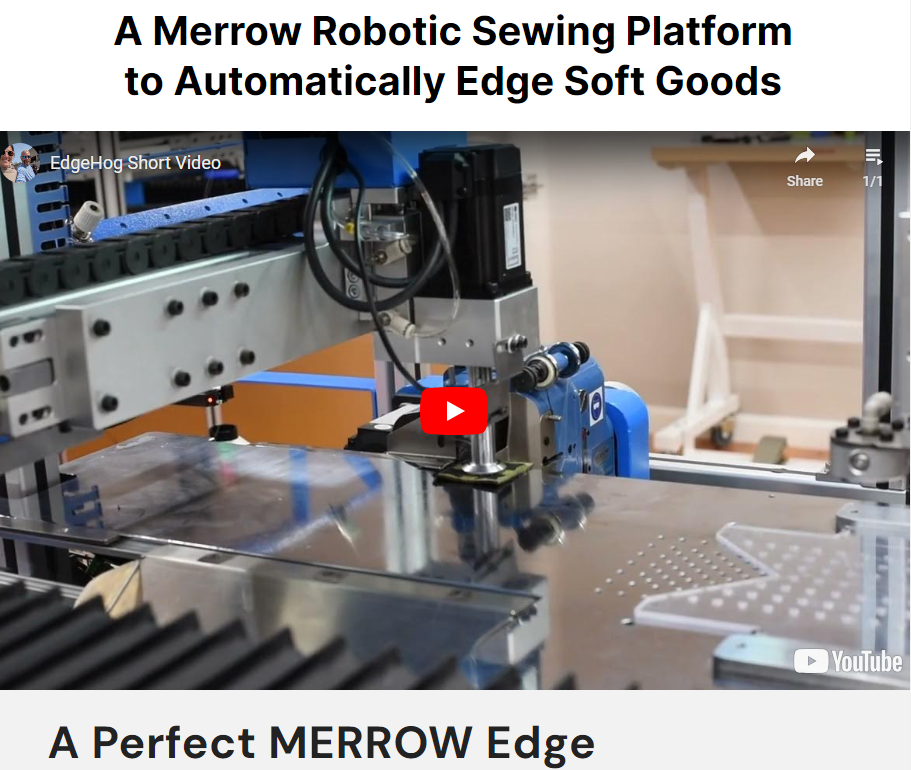

THE MERROW EDGEHOG

Introducing the EdgeHog, a state-of-the-art robotic sewing platform by Merrow, designed to revolutionize the way softgoods are finished. The EdgeHog is a versatile machine, expertly crafted to automate the sewing of edges on a variety of materials that fit its generous work surface. While its featured applications are prominently showcased in the edging of patches and emblems, its capabilities extend far beyond, offering a wide range of sewing solutions.

One of the standout features of the EdgeHog is its operational efficiency – a single operator can effectively manage up to four machines simultaneously, dramatically increasing productivity without sacrificing quality. This multi-tasking capability makes the EdgeHog an invaluable asset in any production setting, from small-scale workshops to large industrial environments.

At the heart of the EdgeHog's performance is its advanced AI technology. This intelligent system not only provides error correction but also adapts seamlessly to new shapes and designs, ensuring consistently high-quality output regardless of the complexity or variability of the materials being sewn. This adaptability is further enhanced by several optical sensors, which provide real-time feedback and adjustments during the sewing process.

The EdgeHog is powered by a robust 220V service and runs on a Windows 10 operating system, ensuring compatibility with most modern digital infrastructures. Accompanying this is a comprehensive graphic design package, enabling users to easily create and modify designs, further expanding the creative possibilities.

Understanding the importance of skill development and ease of use, Merrow offers free training for the EdgeHog. This training ensures that operators can quickly master the machine and make the most of its advanced features, from AI integration to graphic design capabilities.

www.merrowedge.com

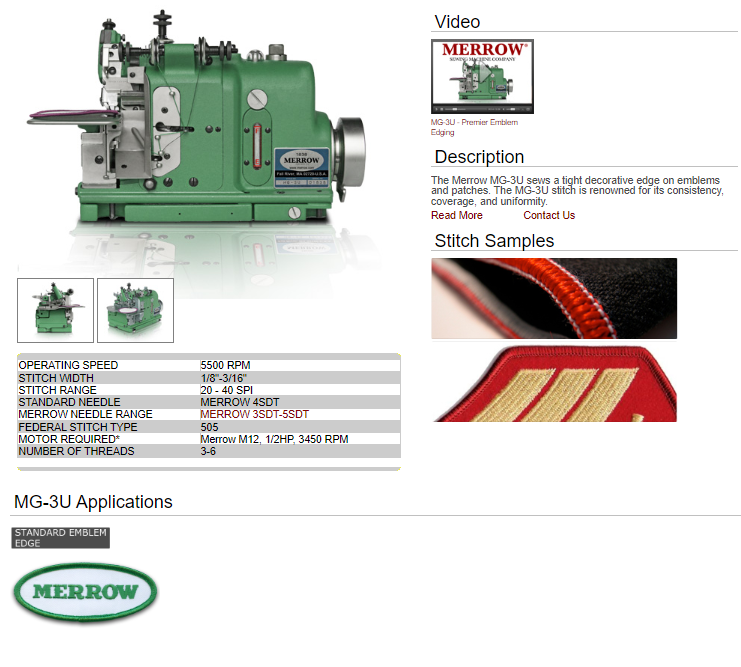

The Merrow MG-3U

The Advantage of the MG-3U

The Merrow MG-3U is a 3-thread industrial sewing machine that is meant for putting a decorative edge on emblems and patches. It makes a 1/8" to 3/16" stitch at a standard rate of 28 SPI (though this can be decreased or increased to 20 or 40 SPI respectively), yet even while running at 5500 RPM still operates under 90 dbA. The MG-3U carries a 10 year warranty, though it is expected to run for years after that with routine care.

WHY it's better

The Merrow Edge is the standard bearer for emblem edging on smaller patches, badges, and insignias. Noticeable for its finish and regularity, the Merrow Emblem Edge is a distinctive mark of quality that can only be made by the Merrow MG-3U.

HOW it's better

The MG-3U uses lightweight moving parts and needle bearings that are manufactured to extremely high tolerances, permitting the fast and smooth starts and stops inherent in intermittent operations like emblem edging. As a result, sewing edges on an MG-3U assures a uniformly finished, unmatched stitch.

WHERE it's used

The MG-3U is a versatile industrial machine that will satisfy the needs of the local emblem shop to the factory producing thousands of patches per day.