PMF GmbH Maschinenfabrikation

Address

PMF GmbH Maschinenfabrikation

Ringstr. 12

66957 Schweix

Germany

Telephone+49 6335 9150

Fax+49 6335 915155

Discover more from us

Follow us on

About us

PMF gives your products an unmistakable look. Where surfaces are decorated with logo’s markings or structures, our machines are first choice.

Proceeding from our solutions for the shoe and leather goods industry, we have expanded our product program continuously throughout the years.

Today we offer machines for almost all industrial sectors: automotive, packaging, printing and paper, plastic and textile, wood and toys, a.s.f..

What counts are your requests.

At PMF you receive the most modern standard machines as well as individual customized machines built to meet your production process and putting into operation – you always have one of our experts at your side.

Through the world-wide service net-work you always receive the best service in every respect.

Technical service and spare parts,

training – we from PMF are always pleased to be at your disposal.

Our product groups

- Textile Treatment

- Printing Technologies

Keywords

- Markiergeräte

- Etiketten

- Thermodruckverfahren

- Sondermaschinen

- Transfer Druckmaschinen

Our Products

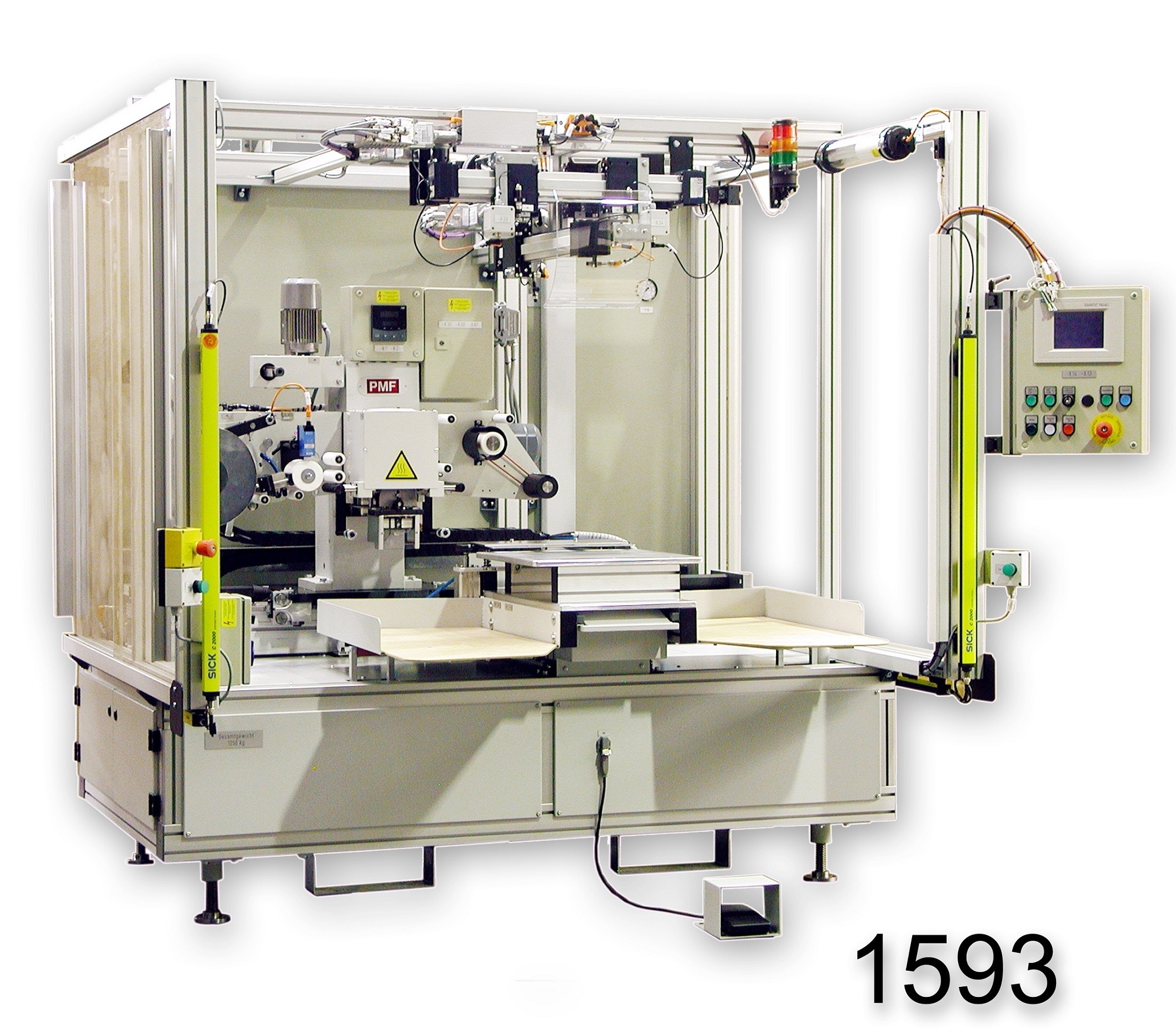

Mod. 1593

Semi-automatic transfer application machine for the Isofix application on the ready made seat cover Transfer station can be positioned linearly Transfer table positionable through motor, deposit tub on both sides Pneumatic clamping holders on the transfer table Electornic temperature regulation with digital display and control of lower set value Dwell time control 0 10 sec. Pressure regulation with gauge Automatic transport of transfer tape through gear brake motor, with sensor control and pneumatic bandbrake and frequency converter Wind-up device for used transfer track and paper track Safety light curtain Integrated switch cabinet and separate control panel Temperature regulation with progammed security device Control over display, recognition of transfer tape end, feeding recognition Positioning of cover and Isofix position over laser marking system Adjustable over bar code reader or manually on the display Adjustable in two axis Height adjustment through motor

Mod. 335

50 kN pressure Embossing area 480 x 280 mm Max. embossing temperature 250° C Release over foot pedal Safety guard with advancing hand guard or light barrier. Indirect air operated drive, stroke of the table upwards Pressure regulation with manometer End of stroke regulation through hand wheel Dwell time control Top counter pressure plate 480 x 280 mm with heating and electronic temperature regulation through sensor up to 200° C. Opens to enable loading and unloading, closes pneumatically over knuckle joint system for the embossing Machinestand with incorporated electronic and pneumatic control

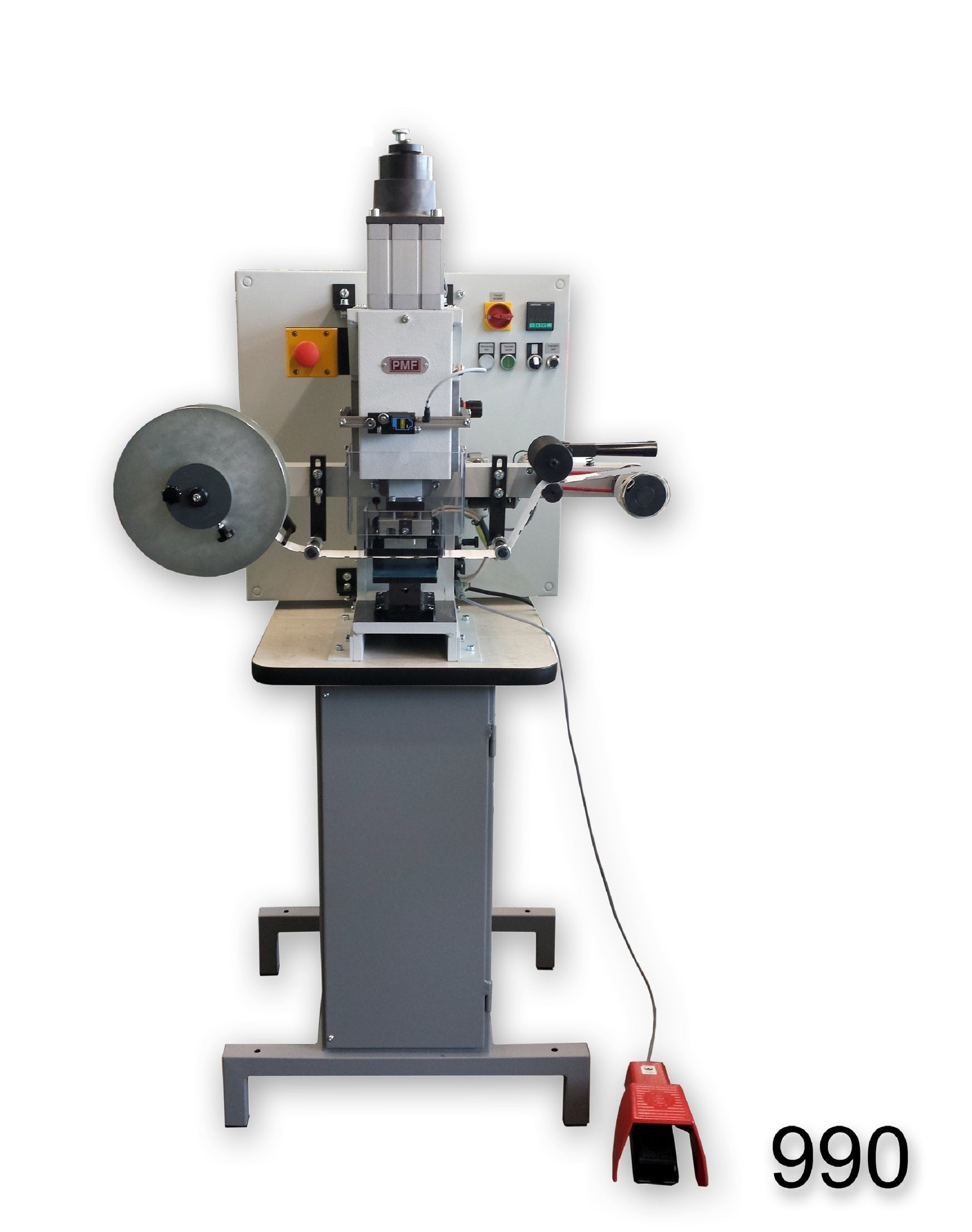

Mod. 990

Pneumatic transfer application machine as table version Direct pneumatic drive Pressure 1,9 kN Automatic transfer tape transport. Transfer head 80 x 100 mm with quick change system for die holding plates Option: End position adjustment

Mod. 950

Automatic lettering,decorating and marking with "transfer labels" from the roll on PMF transfer application machines. The principal features on this design are ultra-modern technology, extremely simple operation and maximum safety. The light barrier controlled decal transport system guarantees an optimum transfer application accuracy. Decal feed track and transfer die are easy to exchange. The machine can be converted and adjusted in a very short time An indirect air operated pressure system, electronic temperature control and pressing time control enable a proper adaptation to the decal and the material being used. An advancing hand guard gives a maximum of safety and an unobstructed view. The machine enables the use of different kinds of transfer tables. From the simplest fixed table, over hand sliding tables to complex special tables, an adaptation to the respective objects is possible.

Mod. 950L

Transfer application machine with laser system Transfer head 55 x 100 mm Quick change system for transfer tools Electronic temperature regulation with digital display and lower set value control Automatic transport of the tape over gear brake motor, with sensor control and band brake Wind-up device for used tape Monitoring of the diameter of the transfer tape through ultrasonic distance sensor Wind-up device for used paper track Transfer table – according to product PMF