ergoCNC – Software for Textile Cutting

ergoCNC – Software for Textile Cutting

Description

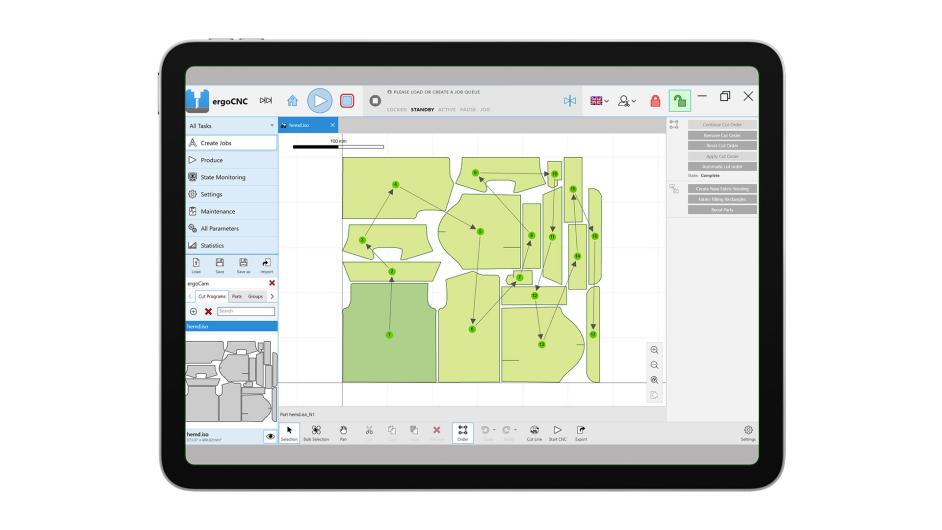

User-friendly job preparation and resource-efficient job planning.

The CNC300 control solution for textile cutting, consisting of ergoCAM and ergoCNC, is particularly impressive with its smart handling and fully automatic optimisation functions. High-precision cutting strategies based on stored algorithms for corners and curves, notches and seam allowances guarantee high-quality cutting – at any speed and for all materials. Elevate your cutting machines to unparalleled performance with our CNC and CAM software solutions, featuring technology-specific algorithms that deliver outstanding cutting results!

PRECISION AND PRODUCTIVITY UNITED

Whether you're cutting carbon, leather, steel, or foam, ProCom's CNC300 control solution's ergoCNC and ergoCAM software excel with perfect precision and maximum cutting speed for all materials. The tailored algorithm for coordinated multi-axis movements, along with technology-specific functionalities, propels all types of cutting machines to peak performance. The result: cutting outcomes that impress along the entire cutting line, whether it's knife, waterjet, laser, or plasma cutting.

THE CUTTING DREAM TEAM

The CNC300 control solution comprises CNC and CAM software:

- ergoCNC – Reduced workload during the cutting process thanks to fully automatic job processing.

- ergoCAM – User-friendly job preparation and resource-efficient job planning for a seamless workflow.

SMART AND INTUITIVE USABILITY

The user-friendly interface of ergoCNC allows you to intuitively adjust all production parameters without the need for extensive training. Numerous specific functionalities ensure optimal cutting results for every material and cutting technology. All functions can be operated both via the touchscreen and with a mouse and keyboard. Task-oriented and role-specific settings provide a clear layout, presenting you only with the information and controls needed for your current task.

TOOL MANAGEMENT MADE EASY

The Material Assistant allows you to quickly and intuitively select the optimal tool for any type of material. Parameter switching occurs fully automatically based on the values stored for the new tool. A signal icon indicates if parameter changes or a material-induced tool change is required. Thus, even inexperienced operators can manage the tools with ease in the shortest time.

YOUR BENEFITS WITH THE CNC300 SOFTWARE

- Highest Precision

- Intuitively Designed Throughout

- Customisability

- Efficient and Cost-Effective

- Integration Into Other Systems

- Always by Your Side

-- More information available on our website --