Rasor Eletromeccanica S.r.l.

RS1

Explore product

RS1

Explore product

RS1

Explore productAddress

Rasor Eletromeccanica S.r.l.

Via Giannetto Mattei 41/43

20044 Arese Milano

Italy

Telephone+39 02 6622 1231

Fax+39 02 6622 1293

Discover more from us

Follow us on

About us

As of today Rasor Elettromeccanica Srl boast the professional continuity of three generation yet with the strong experience got by the founder thanks to his passion and devotion.

Rasor Elettromeccanica Srl was born in Milan in 1946 by founder Mr. Luigi Spinelli that with his inborn talent in technical and precision mechanics matters and exceptional ability successfully realized the first wholly hand-made bench cutter.

Rasor’s products were firstly born for the application in textile industry while now the range has been enlarged to industries for technical textile and composite material production.

The distinctiveness of Rasor is the wholly inside work to start with design of the product, production, packaging, delivery. All thanks to workers professionally grown up together with the Company being in perfect agreement with the founder with the sole target to grant quality of each single produced cutter.

That is still the key point of Rasor and so to be daily engaged with any improvement and open to study and develop new materials and technologies.

Rasor boast an international network of distributors to be successfully present on all the Continents.

Our product groups

- CMT (Cutting, Making, Trimming)

Keywords

- cutters

- cut

- textile

- cutting units

- textile cutters

Our Products

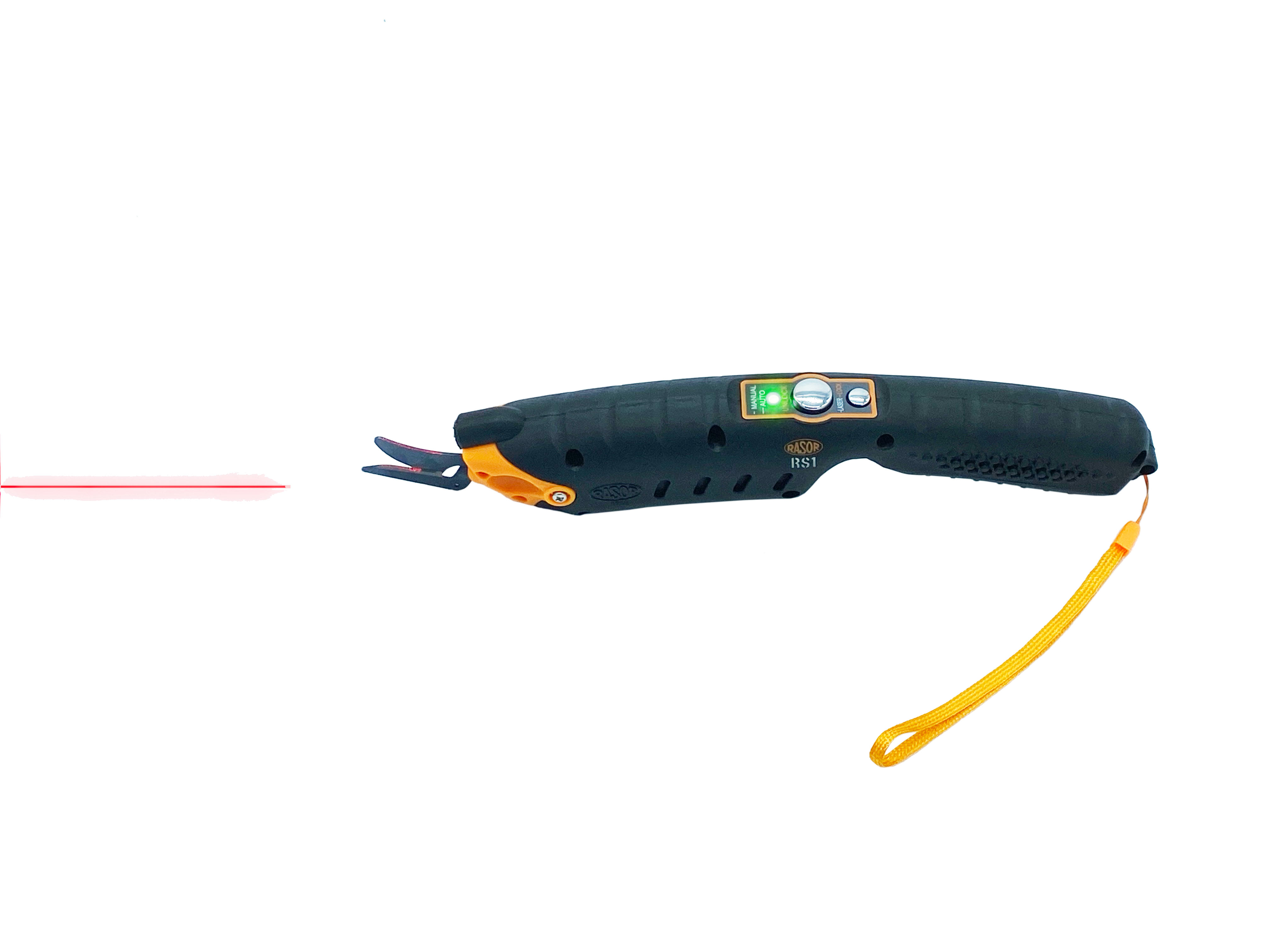

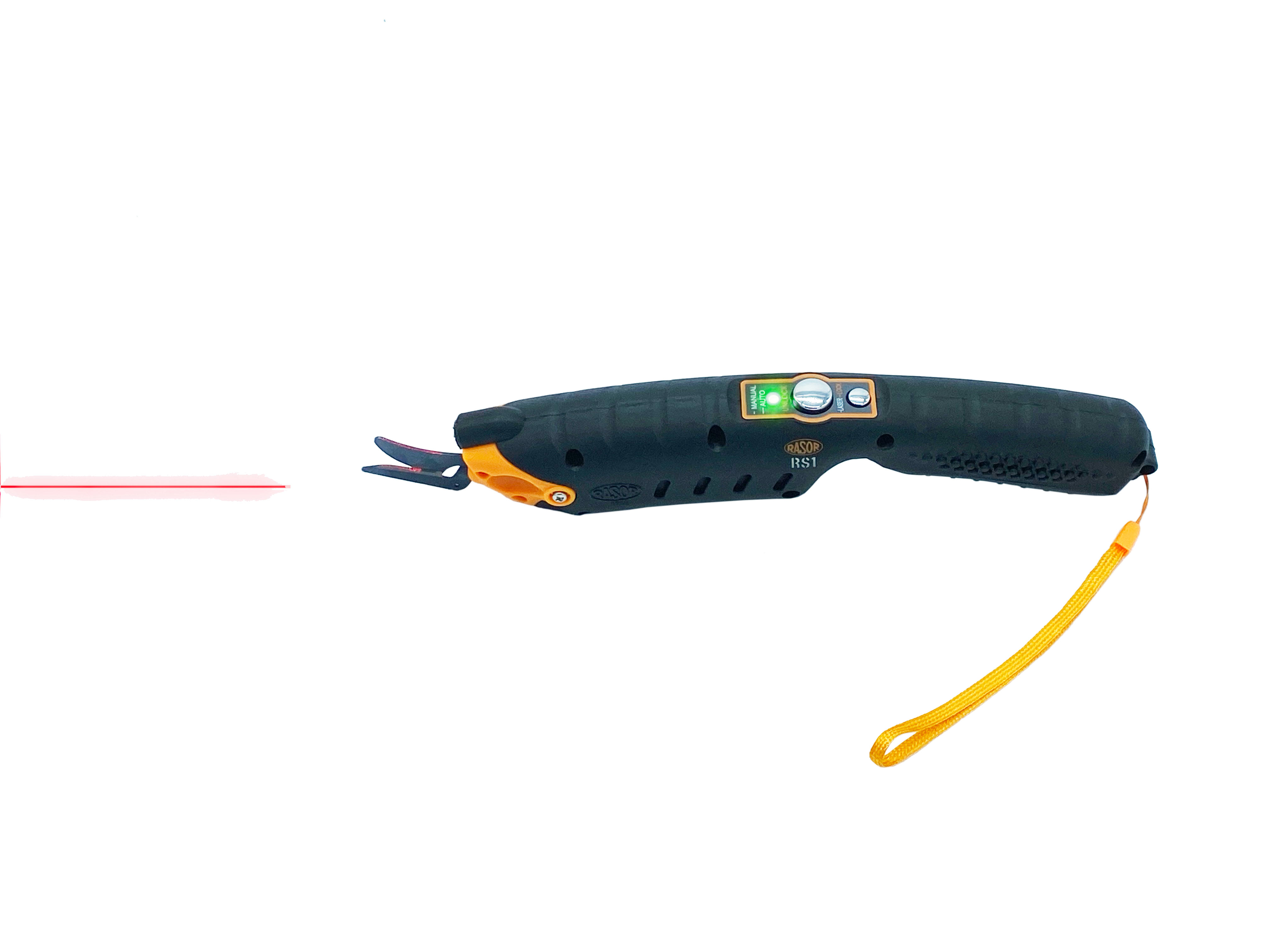

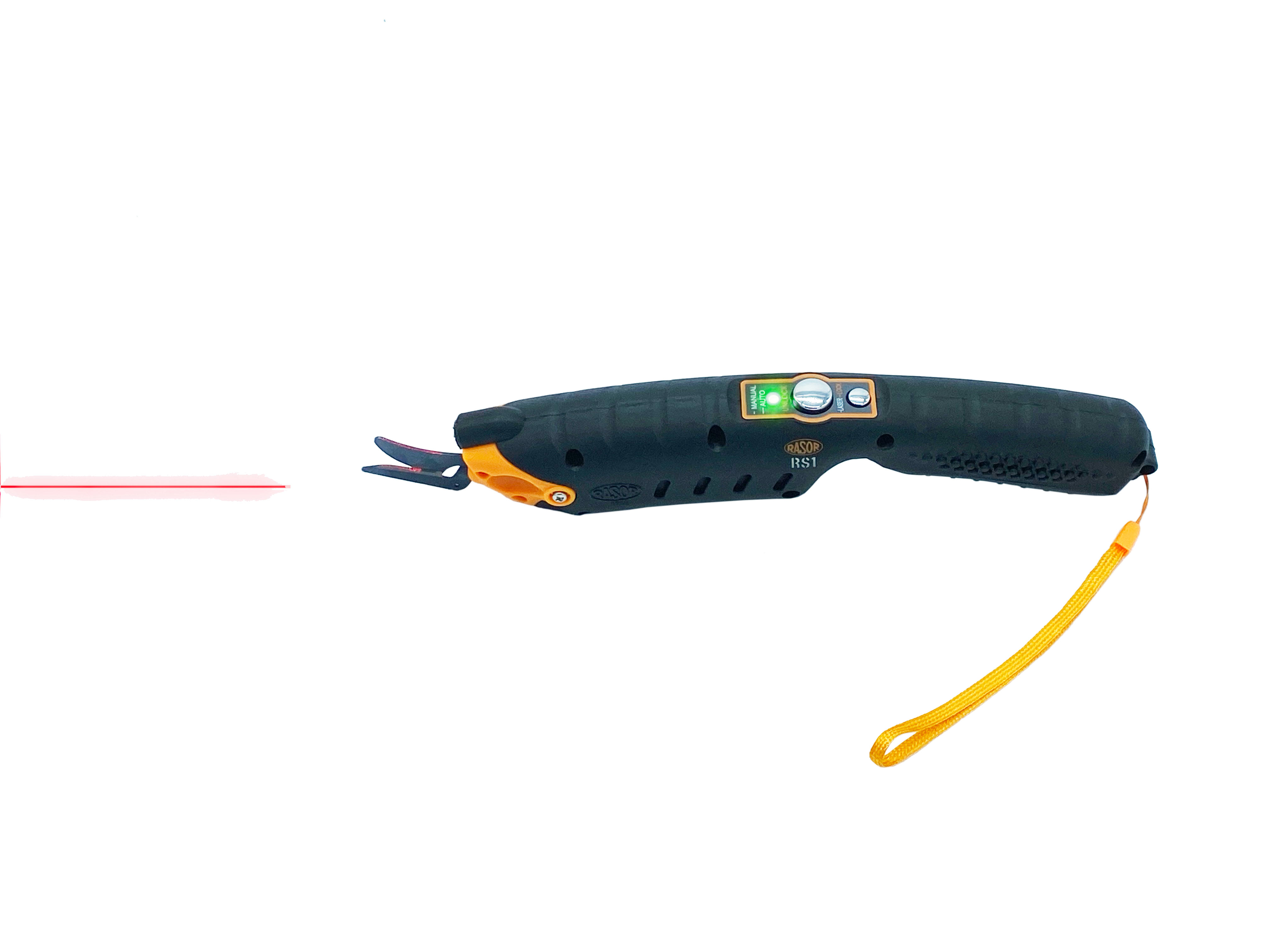

RS1

The new RASOR® RS1 is a professional battery driven scissor with alternating blades. It is ergonomic, strong and has excellent cutting performance. The RS1 has blades with Tungsten steel inlays (Widia®) which assure perfect cut without jam and clean edges of the material. The Li-Ion® technology batteries ensure a long-term use and are powerful with 3.6V and 5Ah. The speed of the motor (19.000 rpm) allows to move the blades at 80 times per second. The smart button technology with Safety-Lock and automatic cutting mode makes the RS1 an unique scissor on the market. The integrated laser light-line allow to follow a line for a straight cut. The Rasor RS1 guarantees long and effortless use thanks to its light weight of only 370 grams, including the battery. Any kind of natural and technical textiles can be cut with the RS1. Also, light plastics, and polymers. Skai, upholstery leather and paper products are also possible. Thanks to its ergonomic and convenient design, it cuts both straight and contour with an excellent view of the material.

NERAPro

The new model NERAPro is the revolutionary hand held battery driven shear for any kind of textile fiber. Unique on the market it combines the cutting potentiality of the model DS504 with a miniature Lithium-Ion 3.7V battery-powered motor. The result is a compact, powerful and reliable cutting machine in just 580 grams of weight. This new version has a PCB board installed which allows a smooth start and an electronic protection from overload. Never has a cutting tool had this excellent weight/performance ratio. The reinforced structure and coupling gear of bronze / steel material generate now 1000 rpm, unique on the market of its kind to obtain this speed allowing its use not only in the textile field but also in the field of light technical fabrics and light leathers. The Lithium Ion battery develops 2400 mAh and is easily rechargeable with the appropriate docking station with LED indicator. The second battery, included in the box, allows a quick replacement so to cut continuously without interrupting the work. The maximum cutting thickness is 9 mm and the new button sharpener allows to revive the cutting edge of the blade in less than ten seconds without removing it. The cutting foot, strong and with a thin shape, allows the cutting of curved profiles with great ease. The new NERAPro is truly an innovative concentrate of power, lightness and ease of use in the field of professional cutting tools.

GRT12M

Model GRT12M is a three-phase cutting unit suitable to cut high thickness in the technical fabrics and composite materials. Launched on the market only a couple of months ago GRT12M gives its excellency to the new geometry of the motor housing of Monster series. The difference between GRT12M and the other Rasor cutting units is given by its motor housing held by a central foot fitted behind the blade in central position. This system spreads the shearing stress and the necessary stress to move the machine through the fabrics on both sides of the cutter and cut is so done perfectly straight and smooth. The knife is half-free on both sides to avoid winding problems even with tough fibers. This is why GRT12M is especially suitable to cut composite materials like glass fiber, carbon fiber and kevlar. The three-phase induction motor is balanced and noiseless. It does not need any maintenance so to be easily used during the production process on 24 hours-a-day. This type of motor together with bronze/steel couplings give the cutting unit to be reliable and resistance in life. The 8-edges 120 mm knife allows a cutting thickness up to 50 mm even for multiple layers. High torque combined with the slow RPM of the knife allow to cut even rubber materials and plastic based material in the field of carpets and industrial flooring. The push button sharpening stone allows the sharpening of the knife edge to be done in less than 10 seconds without removing the knife. The aluminium base is Teflon® coated to reduce friction with the material and can be installed on sliding rails within a small space. GRT12M is especially suitable for the transversal cut and it arranged with an anchor flange to be easily adjusted on fixed or automated hanger. For the stepless trimming process GRT12M is also available in the left side version (specular) as model GRT12SM. The low-cost maintenance and the minimum handling costs make GRT12M the most powerful and reliable cutting solution for any O.E.M. application.