Serkon Makina San. ve Tic. A.S.

Address

Serkon Makina San. ve Tic. A.S.

Deliklikaya Mah. Dirilis Cad. No: 5 Ic. Kapi No: 1, Arnavutkoy 34555

Istanbul

Türkei

Telephone+90 212 486 09 86

Fax+90 212 486 09 89

Discover more from us

About us

The Spirit of Serkon lives on at Six Storeys, 10.000 square meters.

A High Tech Technology Facility with storeys of 1250 sqm Each Europe's Biggest producer in cutting room equipment.

We produce technology for Cutting Rooms Made in Turkey and we export it more than 70 countries worldwide

Serkon is the Leading and sole manufacturer of CNC Cutters in Turkey. Besides CNC Cutters, Serkon has wide range of spreaders, exclusive tables, conveyor systems, CAD System, and inspection machines.

Our product groups

- CMT (Cutting, Making, Trimming)

Keywords

- CAD System

- Cutting Room Equipment

- Fabric Spreading Machines

- cnc cutter

- Fabric Inspection Machines

Our Products

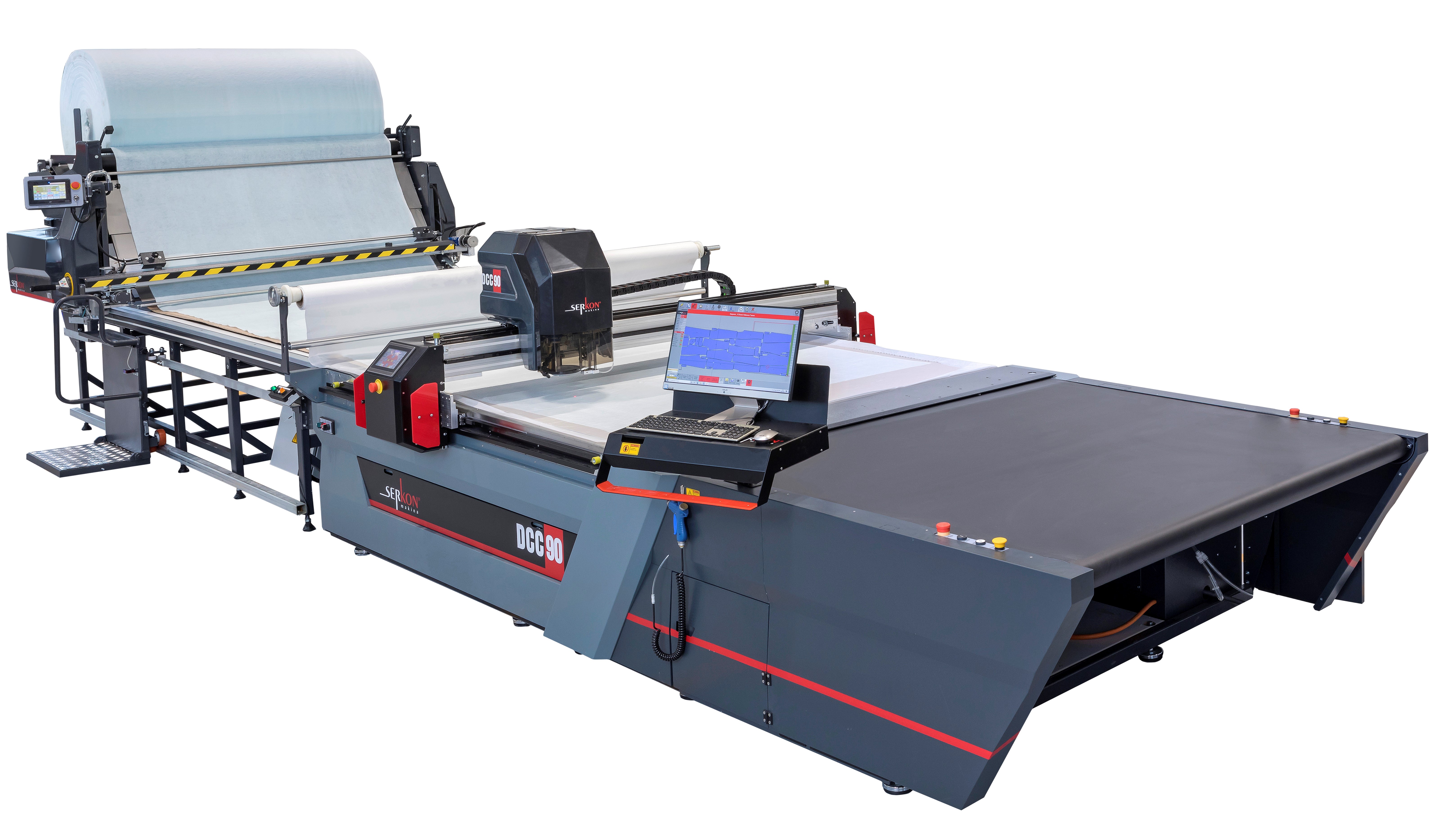

Conveyorized Automatic Heavy Weight Fabric Cutting Machine – Continue Cuttter [DCC90]

A conveyorized cutting table efficiently moves material from the spreading table to the cutter and then moves cut parts onto the bundling area

CAD SYSTEM [Serkon Design Pro / Serkon Marker / Serkon AutoMarker / Iso Cut / Digi Pen / Plotter]

FULLY AUTOMATIC FABRIC SPREADING MACHINE - MINI MASTER [MN3]

MN2 Mini Master allows spreading of full range of available fabrics: from very delicate, thin, elastic and difficult to spread, to thick, heavy fabrics like denim. Thanks to the servo motor driven fabric and main motors, It provides more precious and dynamic spreading. The machine is equipped with a cradle with belt feeding ,double solid PVC belt (not parallel stripes), which guarantees perfect and even grip throughout the fabric width. Electronically controlled “dancer bar” and encoder are available for “tension free” spreading. The machine is equipped with user friendly Industrial PC 10.5 inch Touch Screen Display in where all marker information is available. Intelligent Reporting System is delivering hard data for analysing spreader activity and production. Graphical report is also included. Optionally allows operator to see the patterns through the projector.

FABRIC VISION - AI SUPPORTED FABRIC INSPECTION MACHINE

Fabric Vision - With the artificial intelligence-supported fabric inspection machine, we detect defects and colour-tone differences on the fabric surface.

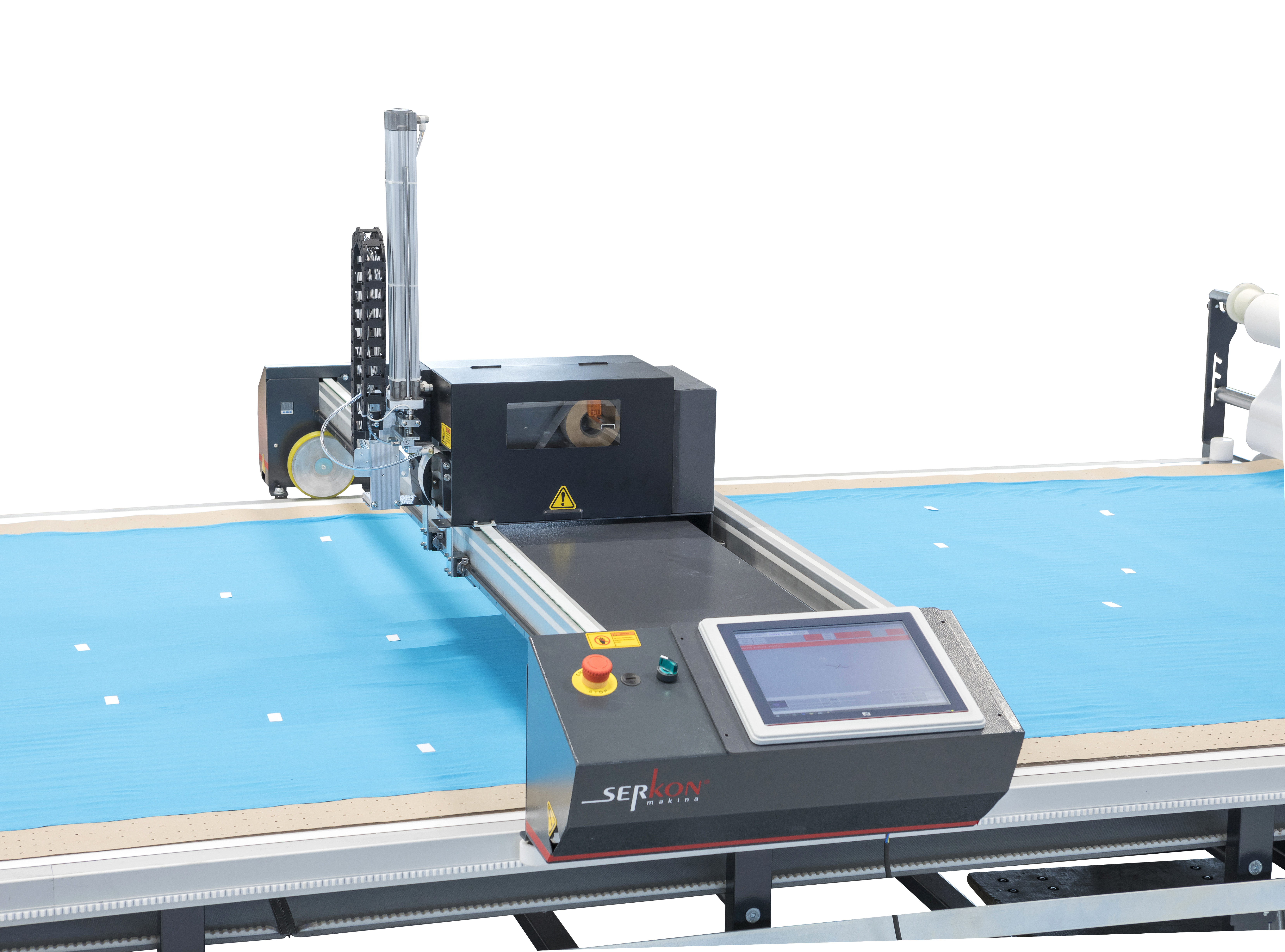

FULLY AUTOMATIC LABELLING MACHINE - MASTER LABELER [MB1]

The Labeller prints out and places a sticking label on each pattern of the marker on the upper ply of the lay directly on the fabric.

The label contains the required information to make each piece easily identified after cutting for proper bundling. It is not longer needed to print out the marker with plotters, to place it on top of the fabric and cut it with CNC Cutters. Master Label runs on the top of the spreading table on special metaillic side rails in order to work fully independently on the lay after spreading and before cutting, without affecting the total working process time. The labels are placed directly on the fabric and not on the plastic seal. They will not be able to move after cutting due to thermoheat printed sticky labels, even the smallest ones and will be perfectly recognizable. It is interfaced with CAD system to collect all required marker data. . It is Possible to print on multiple rows, with different fonts, including bar code. Approximately 100 labels are placed in 10 minutes in Underwear, 12 minutes in kidwear, 14 Minutes Adult Garments and 18 minutes in Upholstery. Laser point is available to set up the starting point. The machine is equipped with encoder along with Servo Motor to guarantee highest possible precision and accuracy.

Our Contact Persons

Sefa Sagyalavac

Marketing/Werbung

Angestellte*r