Sonotronic GmbH Ultrasonics Technology

Address

Sonotronic GmbH Ultrasonics Technology

Becker-Göring-Str. 17-25

76307 Karlsbad

Germany

Telephone+49 7248 91660

Discover more from us

About us

As a pioneer in the Ultrasonic Technology, SONOTRONIC GmbH develops and produces machines, systems and components for the joining of plastics. Our innovative systems are used worldwide by well-known OEMs to produce plastic parts for exterior and interior trim in the automotive industry. In addition, we manufacture high-tech ultrasonic systems for the plastics, packaging, food, textile, medical and environmental industries. With our Global Headquarters in Germany and locations in the USA, China and Spain, we are one of the leading companies in our industry. Together with our dedicated team, we are actively committed to ensuring a sustainable and forward-looking plastics joining technology.

Our product groups

- Joining and Fastening Technologies and Materials

- Textile Treatment

Downloads

Keywords

- Ultraschall-Schweißen

- Ultraschall-Prägen

- Rollnaht

- cut&seal

- Maschine

Our Products

Ultrasonic machines, systems and components for processes and applications in the textile industry.

As an ultrasound specialist, SONOTRONIC provides solutions for intermittent welding, cutting, punching and embossing of thermoplastic textiles and nonwoven. Injection mouldings can also be joined to textiles using ultrasound.

Our ultrasonic systems for welding, cutting, punching and embossing are already

used in various industries, for example:

■ Welding corsetry, surgical gowns, sports equipment or Velcro fastenings

■ Cutting to length, trimming and punching of textiles,

■ Embossing (company) logos in corsetry or working clothes.

SONOTRONIC offers the complete range of ultrasonic components for processing textile. We develop and manufacture the generators, converters, boosters, sonotrodes, anvils and holding tools in our own workshops, based on our many years of experience.

Following equipment is necessary for integration in machines:

■ SONOTRONIC Generator 20/30/35 kHz

■ SONOTRONIC Converters in 20/30/35 kHz

■ SONOTRONIC Boosters in 20/30/35 kHz

■ SONOTRONIC Sonotrodes in 20/30/35 kHz

■ SONOTRONIC Roll Seam Sonotrodes in 35 kHz

Ultraschall-Rollnahttechnologie für technische Textilien

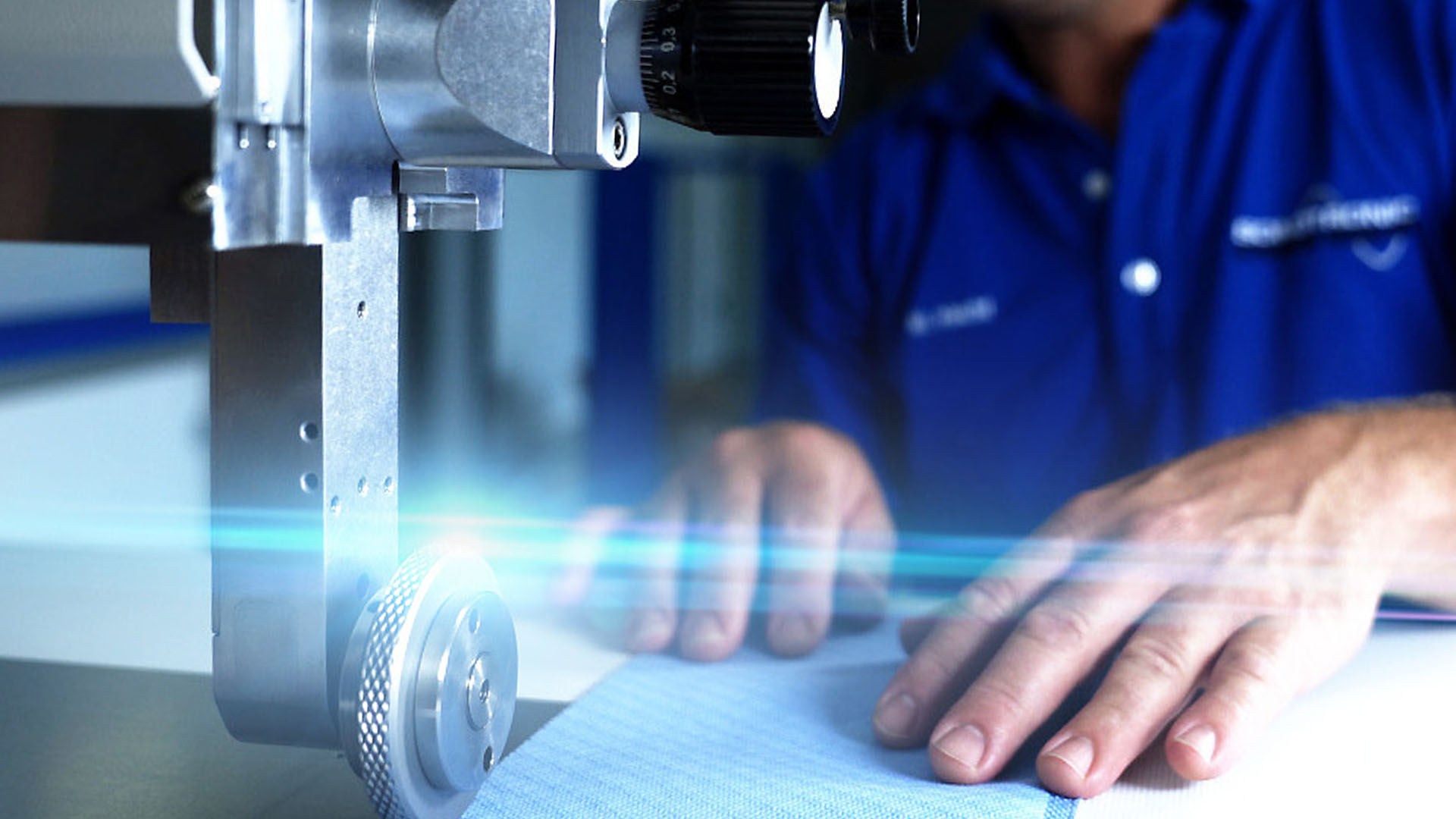

Ultrasonic roll seam module supported at both ends

The ultrasonic roll seam units from SONOTRONIC are suitable not only for continuous sealing but also for the simultaneous cutting and sealing of synthetic textiles.

Continuous sealing seams with high design flexibility

In ultrasonic roll seam sealing, continuous sealing seams are produced by the disc-shaped sonotrode without seam interruptions, for which purpose the roll seam sonotrode has a titanium

mounting on both sides. At the same time the design of the anvil wheels with different contours and widths allows flexibility in seam design.

Simultaneous cutting and sealing (Cut & Seal)

A further application of the innovative ultrasonic roll seam technology from SONOTRONIC is the simultaneous cutting and sealing of thermoplastic textiles with extremely wear-resistant steel sonotrodes. This produces not only fixed seams but also minimal seam projections. During ultrasonic edge cutting the edges are already sealed so that they cannot fray.

Possible applications

In the textile industry ultrasonic roll seam units replace conventional sewing machines. Continuous sealing seams and seams with free geometries can be produced. Fabrics from thermoplastic synthetic fibres are then no longer sewn with one thread but are sealed ultrasonically, and because of this no holes are made in the fabric by needle stitches and there is no subsequent taping.

Besides their use at manual workstations, ultrasonic roll seam systems can also be integrated in existing machines.

The SONOTRONIC roll seam module, supported at both ends, is used for continuous welding and for Cut&Seal in textile processing, in various industrial sectors. It can easily be incorporated in existing and new machine concepts and is made up of three components:

■ Roll seam sonotrode module (with roll seam sonotrode supported at both ends)

■ Anvil module (exchange anvil)

■ Control module

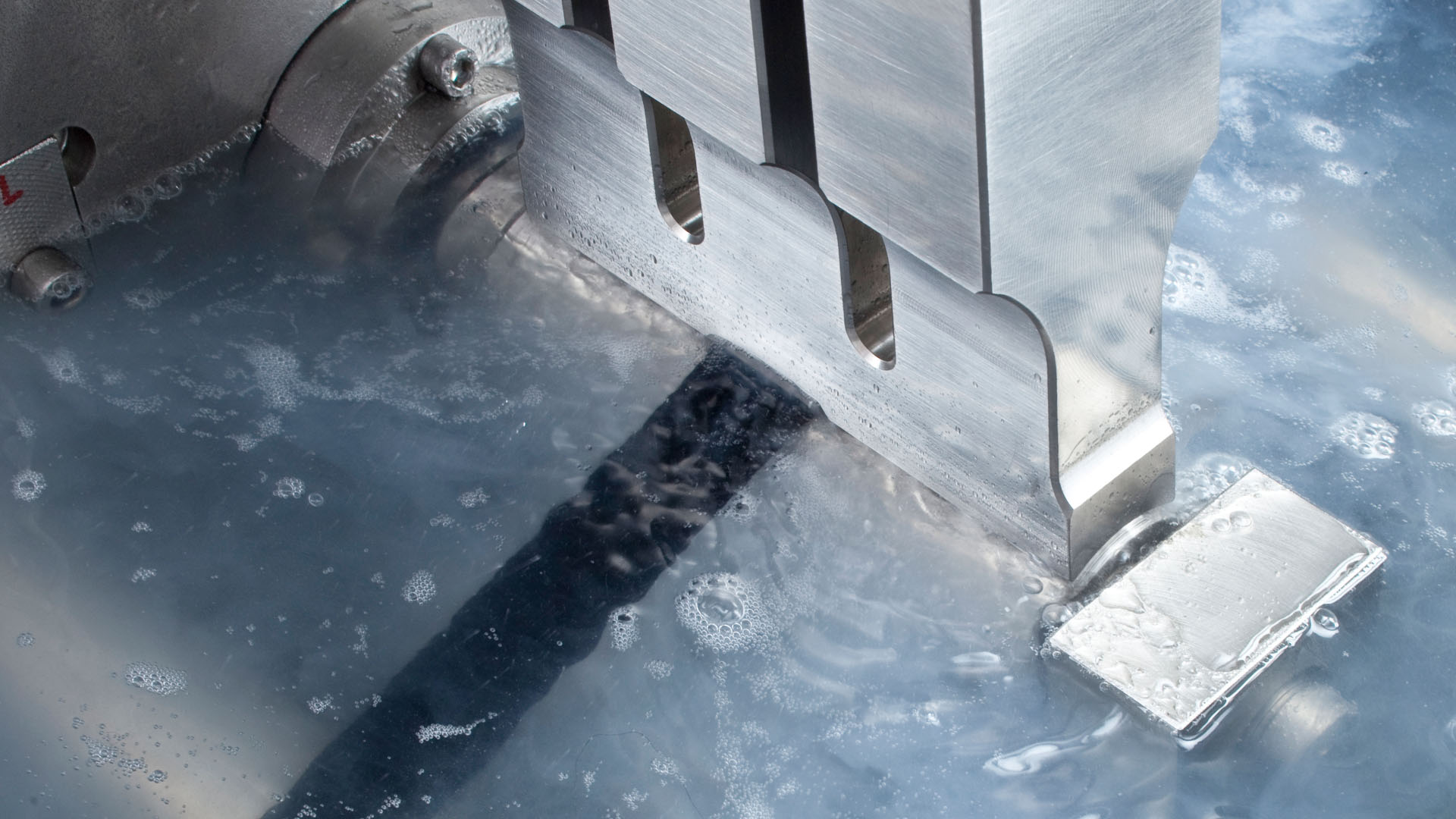

Ultrasonic washing

Apart from making up, ultrasound is also used in the finishing of textiles. SONOTRONIC has adapted the technology to washing and has developed innovative ultrasonic washing units.

Applications

Ultrasonic washing is ideal for the energy-efficient washing out of sizing agent and spinning oils prior to dyeing and for removing non-fixed dye particles from narrow fabrics or broad fabrics, ropes or cord, after thermofixing

Efficient process

Simply passing through an ultrasonic washing unit is enough to replace several baths of conventional, highly tempered systems. At the same time the washing distance is shorter and because ultrasound is used, water and energy consumption, as well as the use of chemicals are reduced when washing.

Incorporation in machines

Depending on the type of fabric or degree of soiling, one or more directly connected ultrasonic washing units can be linked into finishing processes. Because of the compact design, subsequent installation in existing systems or incorporation in new machine concepts is a simple matter.

Ultrasonic systems for processing technical textiles

Technical TextilesThe use of ultrasonic improves the CO2 balance

The textile industry is an important supplier for the clothing industry, but also for the automotive industry and plastics industry, medical technology and the construction industry. A key advantage of SONOTRONIC's solutions for the textile industry is that they are very energy-efficient compared to other technologies. With the highest performance and optimum results, they are extremely efficient. The advantages of ultrasonic technology can optimize many applications and processes in the textile industry.

Where is ultrasonic used for textiles?

Our technologies for ultrasonic welding, ultrasonic roll seam welding, ultrasonic cutting, ultrasonic punching and ultrasonic embossing of textile materials have already established themselves on the market. Our customers include manufacturers and users of technical fibers and textiles, e.g. the nonwovens industry, vehicle construction, technical textile manufacture, mechanical engineering and many others.

Prägen mit Ultraschall

Embossing with ultrasound

With ultrasonic embossing, individual texts or logos can be stamped with little force into, for example, artificial leather, corsetry or non-woven fleeces. Ultrasonic embossing units are used as built-in components both in standard and special machines in the textile and automotive industries.

Little force and embossing time

The thermoplastic material is heated by the ultrasonic oscillations, with the result that the amount of force used in ultrasonic embossing is significantly less than in mechanical processes. The sonotrode presses the heated material into the anvil, by which it is very quickly transformed on the surface. The result is top-quality, visually appealing embossings.

Advantages:

- Short embossing time

- Little application of force

- Environmentally friendly and energy-saving