The exhibitors & products at Texprocess 2026 will be available here from mid-January 2026.

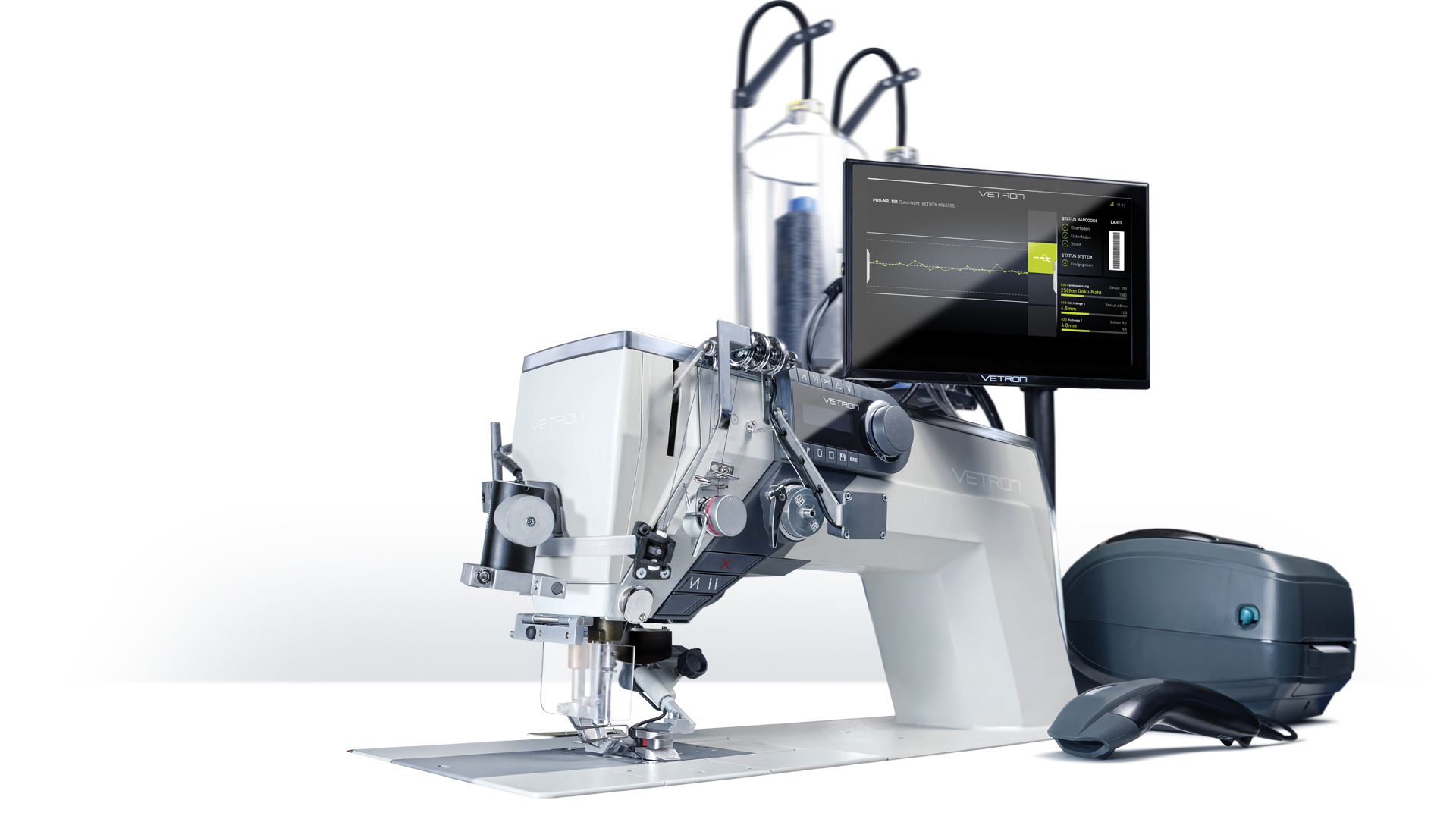

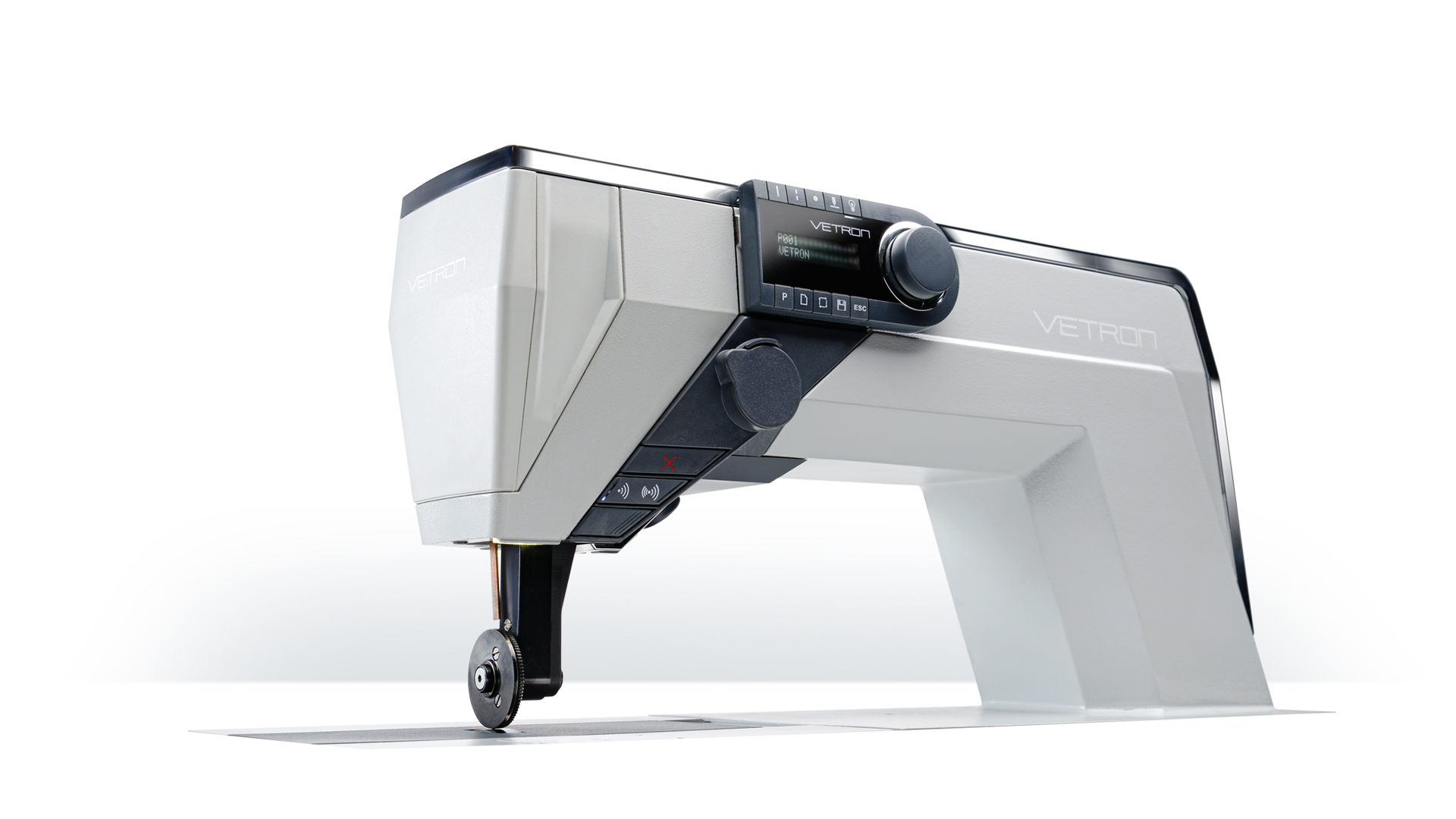

VETRON 5374-30/25 Hot-air taping machine for welding continuous seams on water-resistant, waterproof and breathable materials (slant post the back)

VETRON 5374-30/25 Hot-air taping machine for welding continuous seams on water-resistant, waterproof and breathable materials (slant post the back)

Description

Hotair welding machines are typically used to strengthen and seal seams in the textile and leather industry. Compressed air is heated up to several hundred degrees Celsius by electricity and is blown onto the tape coated with thermoplastic glue...

...the Innovation

ENERGY SAVING OF MORE THAN 90%

The innovation of the VETRON hotair welding machine is based on the development of a new air heater in combination with consistent reduction of heat losses and a newly designed air nozzle. The air supply can be stopped at any time without damage of the heater. The nanoporous thermal insulation and the optimization of the air channel are also reducing energy losses.

The new designed nozzle optimizes the energy transfer to the tape. As a result, the required amount of hot air could be reduced to a fraction.

Comparison tests revealed a possible ENERGY SAVING OF MORE THAN 90% compared to previous systems!

- ENERGY SAVING OF MORE THAN 90% compared to previous systems

- No air noise in pause mode

- Slant from back

- Heating power 700 Watt

- All welding parameters can be programmed and thus reproducibility

- Up to 199 programs can be created

- With integrated, programmable tape pulling and tape feeding device

- Integrated tape cutter

- 25 mm hot air nozzel with integrated tape pre-heating (patent pending)

- With adjustable puller heating

- Tape width from 5-25 mm adjustable

- Adjustable puller pressure

- Programmable welding speed, separatly adjustable for upper an lower puller wheel

- Programmable welding temperature

- Lower puller wheels selectively made from steel or silicon

- Puller wheels 26 mm width (other widths on request)

- Puller wheels diameter 45 mm