Beschreibung

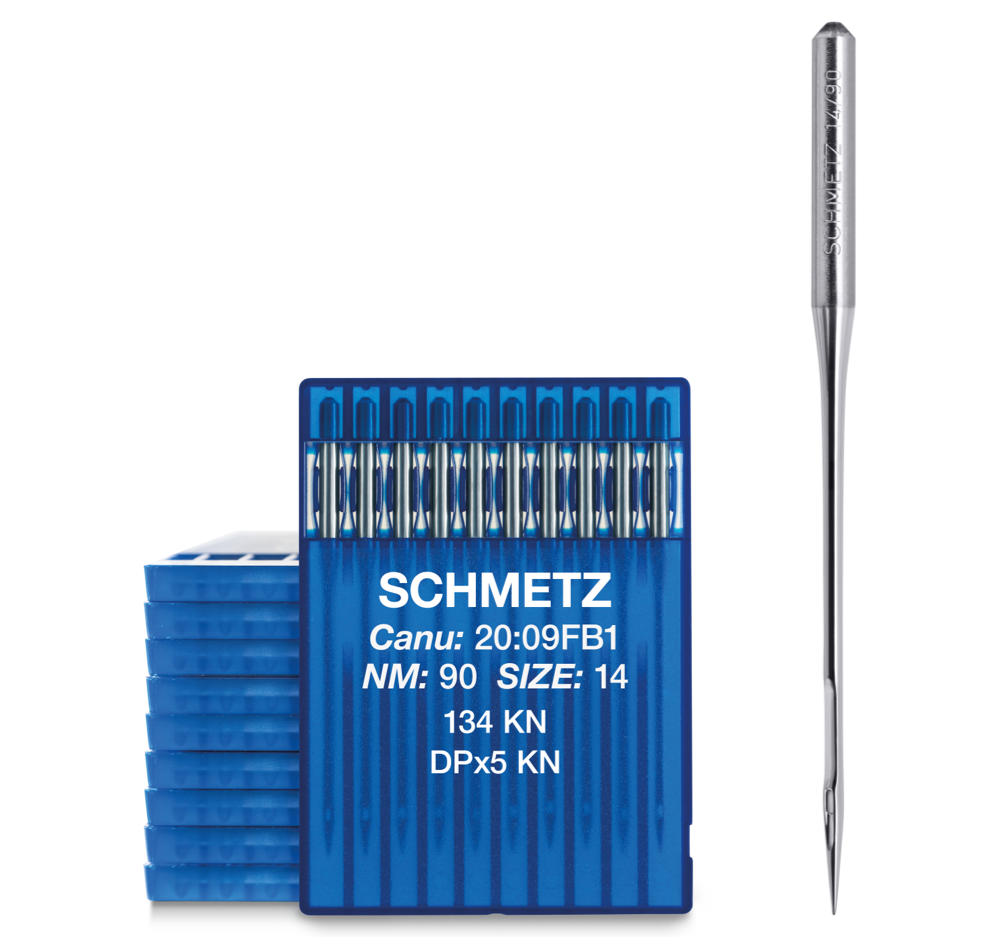

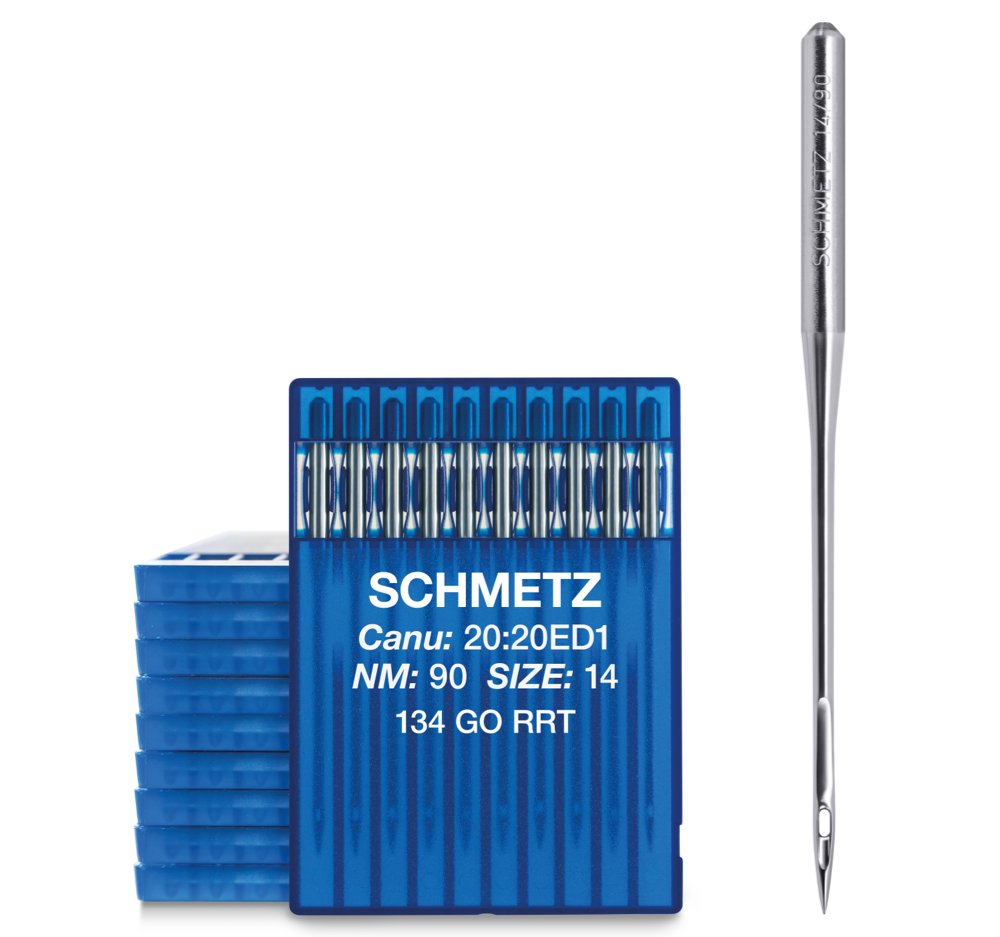

SCHMETZ NIT Nadeln

Spezielle Antihaftbeschichtung mit hervorragenden Gleiteigenschaften

Zum Schutz vor Korrosion werden Industrienähmaschinennadeln mit Hartchrom beschichtet, aber auch zur besseren Gleitfähigkeit, da diese Beschichtung die Reibung während des Nähvorgangs verringert. Für Standardanforderungen ist diese herkömmliche Beschichtung mehr als ausreichend. Anspruchsvolle Nähprozesse erfordern manchmal den Einsatz von Nadeln mit einer speziellen Beschichtung, etwa bei der Verarbeitung von abrasiven Materialien oder Stoffen mit hohem Chemiefaseranteil.

Reibung und hohe Nähgeschwindigkeiten erzeugen hohe Nadeltemperaturen. Es gibt ein paar Möglichkeiten, die Nadeltemperatur niedrig zu halten. Dennoch bleibt in manchen Fällen geschmolzenes Kunststoffmaterial an der Nadeloberfläche haften und verstopft die lange Rinne und das Nadelöhr, stört den Nähvorgang oder beschädigt sogar Material und Faden.

Die NIT-Beschichtung ist eine Lösung für viele dieser Situationen.

Vorteile:

- Verhindert auch bei kritischen Materialien das Anhaften von Schmelzrückständen an der Nadel, dadurch bleibt die Nadel länger sauber

- Fast 20 % bessere Gleitfähigkeit des Fadens durch das Öhr einer NIT-beschichteten Nadel:

- Einfaches Gleiten des Nähfadens durch das Nadelöhr, wodurch die Verwendung von sehr dicken Nähfäden möglich ist

- Leichtes Eindringen in harte Materialien durch hervorragende Gleiteigenschaften der Oberfläche

- Optimaler Fadenschutz

- Vermeidet Fadenbruch

- Weniger Fehlstiche

- Mehr Kontinuität im Nähprozess durch reduzierte Stillstandszeiten

Anwendung:

- Materialien mit niedrigem Erweichungs-/Schmelzpunkt

- Menschengemachte Materialien

- Materialien mit hohem Chemiefaseranteil

- Materialien mit besonderer Veredelung, z.B. Flammschutzmittel, Farbe, Modifizierung von Textilfäden oder Oberflächen hinsichtlich Trage- und Pflegeeigenschaften

- Schwere und harte Materialien

- Beschichtete Materialien

- Bei Verschmieren von Nadel und Öhr bei Verwendung von verchromten Standardnadeln