powder metallurgy .SEWING MACHINE PARTS

Beschreibung

Since 1987, in order to adapt to the growing needs of the market and enhance product competitiveness, we have increased capital and expanded a new factory at the current location. We make budgets to purchase new equipment every year and send personnel to Sweden, Japan and other countries for inspections to absorb the new pulses and trends of the international powder metallurgy market. Materials technology information improves the company's mold design and powder molding technology. It also spent 30 million yuan to purchase a German MAHLER sintering furnace and a 250-ton powder molding machine. Combined with foreign material technology, high-strength powder parts can be produced. Its characteristic is that it can reach HRC30~40 without heat treatment, and can avoid the modification of general traditional heat treatment. Worrying about hardening can provide an alternative to improving quality and reducing costs.

Provide customers with the most comprehensive and comprehensive development consulting and services. The company pays special attention to the cultivation and development of talents. Our quality policy is: "We are not afraid of economic downturn, but we are afraid of poor quality." Based on sophisticated equipment and excellent technical personnel, our company's most sincere commitment to customers is in quality control. We obtained ISO9001 quality certification in 2002, and the annual quality target defective rate is less than 0.45%. Under strict control, we will try our best to make commitments to our customers and continuously reduce costs.

We have been professionally manufacturing powder metallurgy parts for 20 years. We account for more than 50% of the supply of sewing machine powder parts. We continue to receive orders from large companies and other major manufacturers, and receive "quality and excellent third-party" reviews. In the past five years, the growth rates of our woodworking machinery, automobiles, motorcycles, and power tool parts have all been above 20%, and other industries have performed better.

Looking forward to the new year, with the trend of rising material and processing costs, how to improve efficiency and reduce costs is the primary consideration for enterprises to continue to grow. The characteristics of powder metallurgy parts can meet this demand. We hope to provide more choices for domestic and foreign manufacturers.

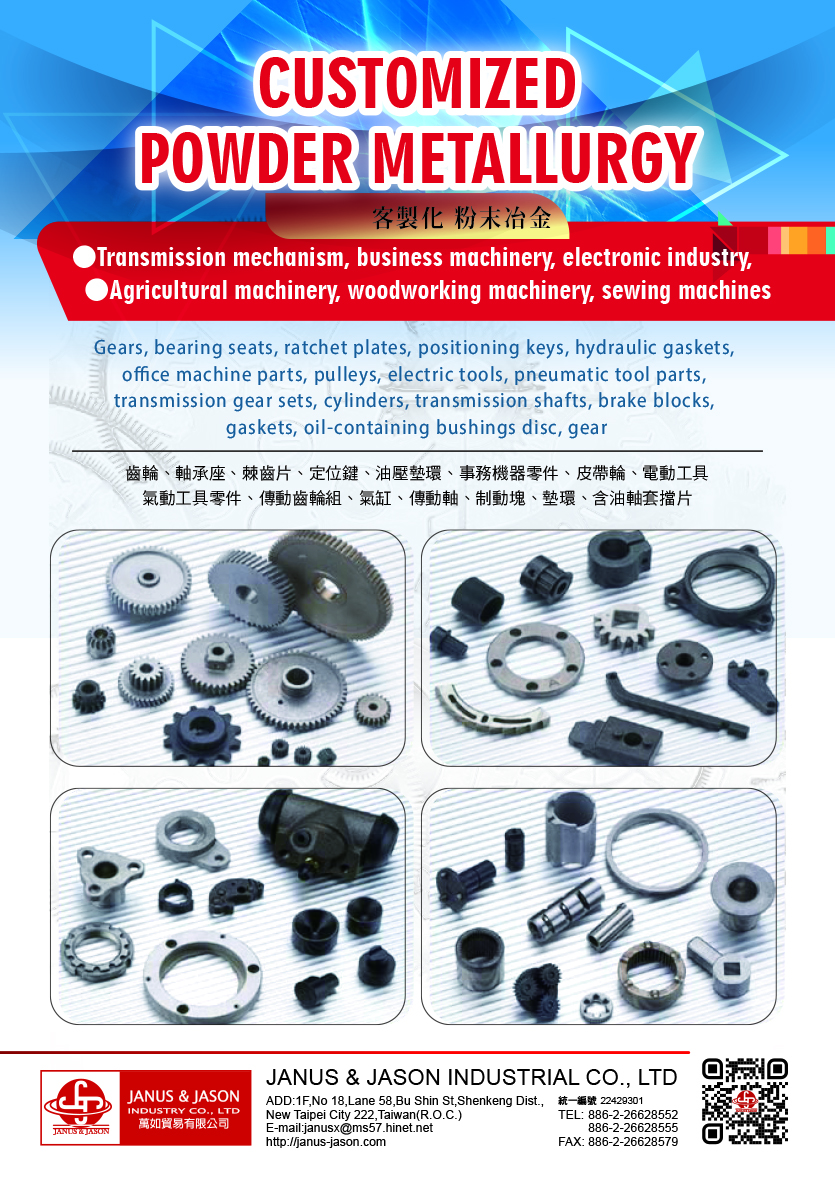

● Transmission mechanism, commercial machinery, electronic industry,

●Agricultural machinery, woodworking machinery, sewing machine accessories

Gears, bearing seats, ratchet plates, positioning keys, hydraulic gaskets, office machinery parts, pulleys, electric tools, pneumatic tool parts, transmission gear sets, cylinders, transmission shafts, brake blocks, gaskets, oil-containing bushing disks, gears

Material-saving (material-saving)

When manufacturing parts with complex shapes using traditional machining methods, a lot of waste is produced, but when manufacturing parts using powder metallurgy methods, there is very little waste, which can save material costs.

Labor saving (saving process time) Time-saving

When using traditional processing methods to manufacture parts with complex shapes, more processing steps and time are required, and the costs and expenses are higher. However, when using powder metallurgy to manufacture parts with complex shapes, fewer processing steps are required. It takes less time and its cost and expenses are much reduced.

Suitable for mass production (low-cost) Mass Production & Low-cost

The mold is pressed into a compacted body by a powder forming machine. Its forming speed is much faster than cutting processing, so it is suitable for mass production.

High dimensional accuracy and good dimensional repeatability (precision size) Precision

The highest precision of mechanical parts formed and sintered by powder cold pressing can reach 0.0005 inches, and the surface is smooth. This quality is similar to the quality of moderately ground workpieces in traditional processing, and the required construction process is only pressurization and sintering, so it is Powder metallurgy is the cheapest processing method to produce parts. Parts manufactured by powder metallurgy are formed by molds, and the difference in dimensional changes between parts is very small, so the dimensional repeatability is good and the precision is high.

https://janus-jason.com/contact

janusx@ms57.hinet.net

Adresse

JANUS & JASON INDUSTRY CO., LTD No. 18 Lane 58, Bu Shin St., 1F, Shenkeng Dist.

New Taipei City 222

Taiwan

Telefon+886 2 2664 0662

Fax+886 2 2662 8579

Entdecken Sie mehr von uns