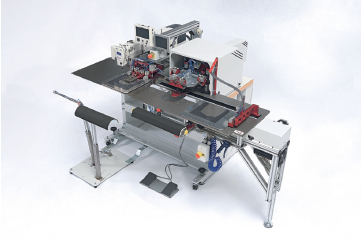

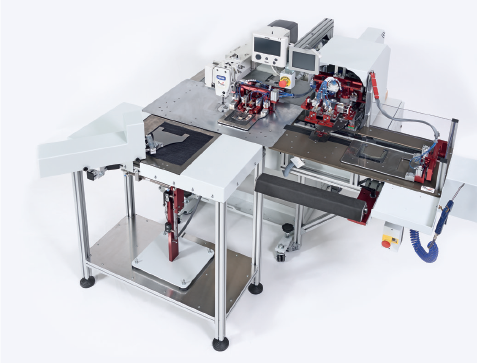

9280SPV

Beschreibung

FEED OF THE ARM UNIT

Feed of the arm unit, 3 needle, chain stitch, special design for lap felling and/or double-lap seaming like yoke sewing, back seat, in-seam and side-seam operations for jeans, casual trousers in general, working clothes, denim jackets, etc.

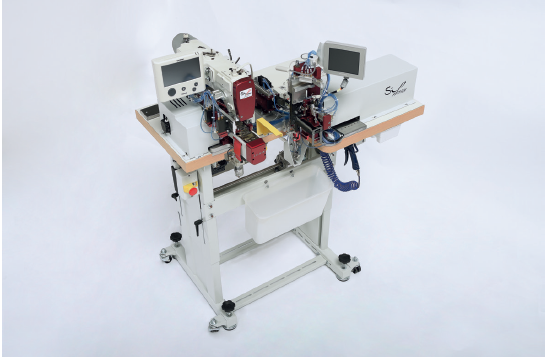

HIGHLIGTHS

- Direct Drive Electronic Puller, transmission by Step Motor, ensures a perfect synchronization with the sewing head;

- Perfect timing means no waves in the seam, no puckering, perfect stitch quality!;

- Sensor detecting the thickness: the work-station automatically adjusts the pressure on the presser foot bar along the seam in order to avoid to skip stitch or un-constant stitch length;

- Automatic dynamic speed control on thick area;

- Automatic dynamic presser foot edge device controlled by thickness sensor for constant seam margin on crotch – back rise area;

- Automatic pneumatic chain cutter controlled by photocell;

- Common electronic servomotor as other units of Sip-Italy range;

- Sewing head made by Brother Japan;

- Dynamic take up lever for attractive balloon stitches even with thick sewing threads;

- Full pushbutton operation. The stitch length can be changed simply by pressing a button and changing the parameter on the console. Very easy setting!;

- Reverse lap folder made in Italy;

- Standard consumable parts, available in all markets with lowest running cost.

PRODUCTIVITY

Yoke seam:

from 200 to 300 pairs of jeans / 1 hour

Back rise:

from 250 to 350 pairs of jeans / 1 hour

Inseam sewing:

from 130 to 180 pairs of jeans / 1 hour

Side seam sewing:

from 100 to 130 pairs of jeans / 1 hour

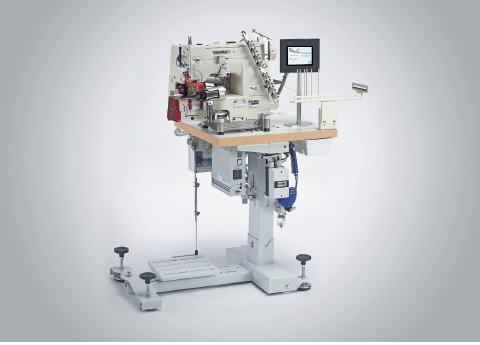

TECHNICAL DATA

Sewing head utilized:

three needle chain stitch unit, heavy duty, manufacture by Brother, model 9280, sub class 5 or 7, Made in Japan

Max sewing speed with all thickness of fabric: 4.500 rpm

Stitch length: from 1 to 5 mm

Standard needle gauge: 6.4 mm = 1/4”

Presser foot lifter: pneumatic

Motor: standard servo motor EFKA, made in Germany

Power supply and air consumption:

0.6 Kw - 220 Volt, mono-phase 50/60 Hz

0.3 liter/cycle at a pressure of 5.5 bar

Size and weight of the workstation:

96 x 73 x 140 cm – 140 Kg

OPTIONS

- Option needle gauge: 4.8 - 5.6 - 7.2 - 8.0 - 9.6 mm;

- Automatic dynamic presser foot edge device controlled by thickness sensor Item Code SIP.A.000328;

- Mechatronic device for super stretch fabric Item Code: SIP.A.000856;

- Folder for super stretch made in Italy Item code GO 180SPE;

- Extended plate for reverse yoke

- Item Code SIP.A.000440.

Adresse

Sip-Italy S.r.l. Società Benefit

Via Maestri Del Lavoro 12

37059 Zevio Verona

Italy

Telefon+39 045 1117 0246

Fax+39 045 605 1645

Entdecken Sie mehr von uns