Vomatex GmbH Bügelunterlagen

Adresse

Vomatex GmbH Bügelunterlagen

Hinterm Sielhof 27a

28277 Bremen

Germany

Telefon+49 421 552374

Fax+49 421 534814

Entdecken Sie mehr von uns

Folgen Sie uns auf

Über uns

VOMATEX is specialised in supplying high German quality press paddings and coverings for industrial clothing presses and ironing tables. Big and important clothing factories and machine manufacturers worldwide trust in our heat and pressure resistant materials and our experience collected in over 50 years of successful work.

Moreover our products are suitable for many other applications like textile bonding, fusing, thermo transfer printing and bending in industries like shoe, glass, aluminium, furniture, advertising and many others. We are exporting our wide range of superior articles worldwide, especially to all countries that are producing clothing for the international markets. The majority of our articles is produced in Germany, some in countries of the European Union, and only few special items by leading manufacturers in other parts of the world. They comply with the latest regulations to save the environment and the health of users and consumers.

VOMATEX products are made of valued raw materials and are processed with the most advanced production methods to meet highest requirements. We are aware that our spare parts are essential for your continuous production. For this reason we keep a huge stock of all articles enabling us to dispatch all orders within a very short delivery time.

Moreover you can rely that our qualified staff will put all knowledge into a fast and reliable processing of your orders. For example we take utmost care to issue every single required document completely and correctly in order to avoid any complications at the export or import formalities. We would like to emphasize that the high quality articles of VOMATEX are more durable than cheap imitations. Due to the extended replacement interval your machines can work continuously for a much longer period of time and fabricate a constantly good result. So whenever you require a heat resistant and pressure absorbant layer please do not hesitate to ask VOMATEX.

VOMATEX – Worldwide leading supplier for high quality heat and pressure resistant materials mainly used for industrial ironing machines.

- VOMAPOR silicone/foam

- VAU-SIK foamed silicone

- 3D Mesh Fabric

- Multi-Stretch

- Needlefelts of Aramid and Polyester

- Metal and Polyester wire screen mesh

- Heat resistant fabrics

- PTFE coated fabrics and foils

- PTFE coated transport belts

- Accessories

Excellent German quality for a constantly superior pressing result.

We are looking forward to provide detailed information about our wide range of high quality products.

Unsere Produktgruppen

- Joining and Fastening Technologies and Materials

- Finishing

Mehr über uns

Special Interests

German Quality Foams, Felts and Textiles

Downloads

Keywords

- ironing covers

- press covers

- pressure and heat resistant

- apparel garment pressing machine covers

- permeable textiles foams felts

Unsere Produkte

Heat and pressure resistant silicone foams

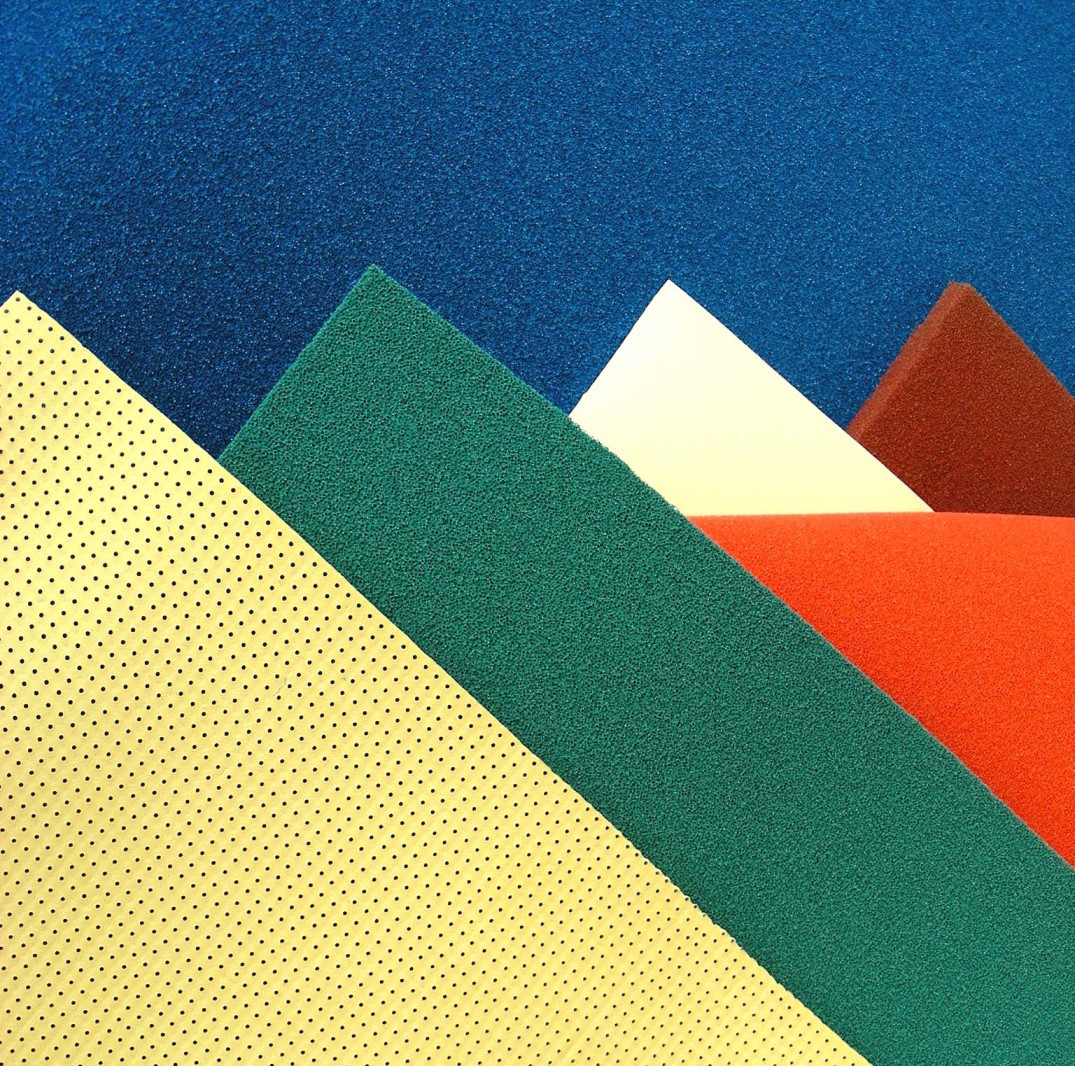

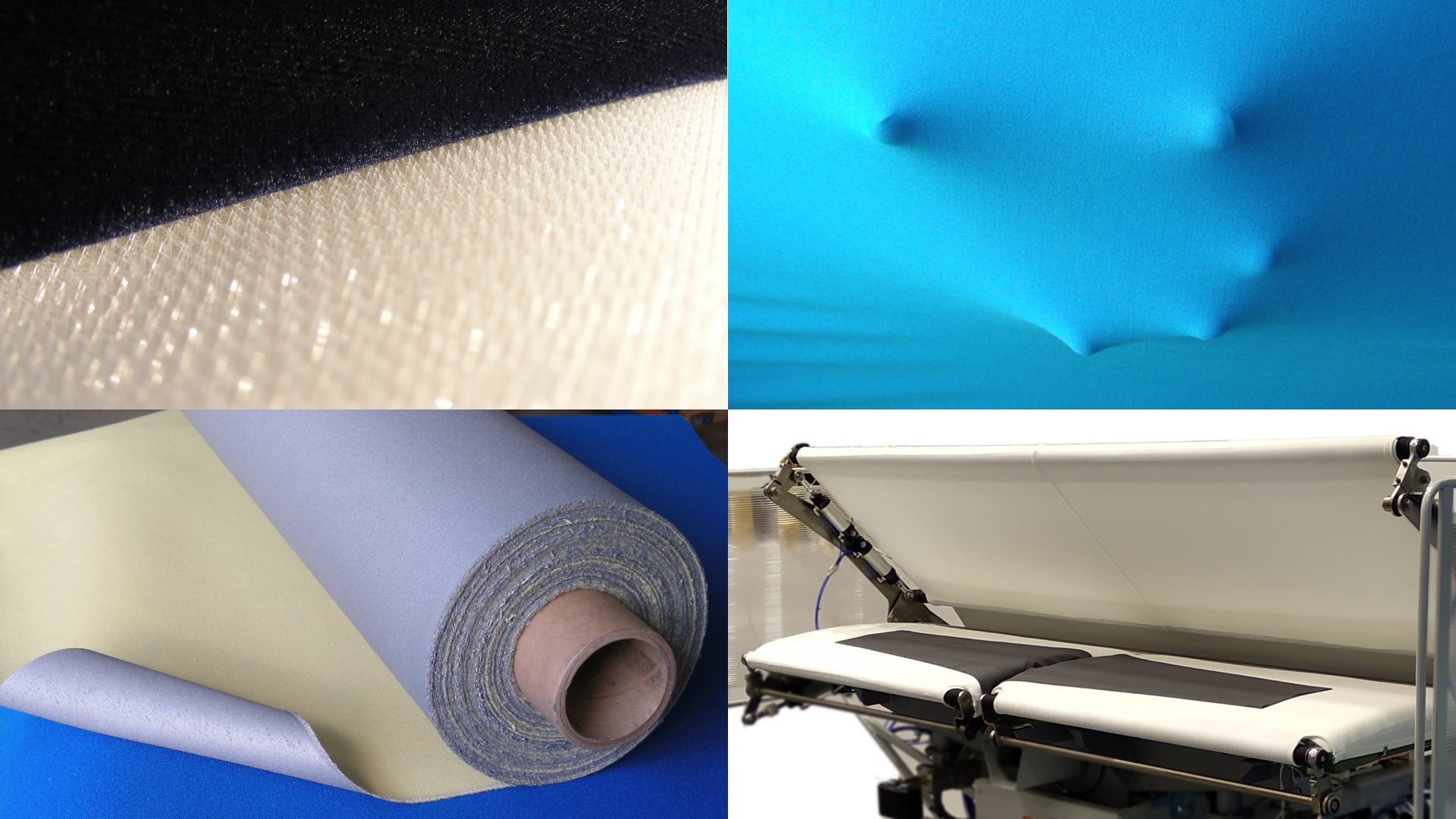

VOMATEX supplies a wide range of foams to the clothing industry and other branches worldwide. Our most expensive but also most durable foams are made of silicone. They are available in impermeable qualities for dry pressing (e.g. transfer printing) and permeable qualities for steam pressing.

The perforated VAU-SIK foamed silicone is made out of high quality silicone. It is permeable and can be used directly upon the hot metal plate. VAU-SIK sheets will last up to 5 years, they are durable elastic, distribute the steam and protect the upper layers and the clothing. VAU-SIK sheets are the indispensable base for every high quality padding.

VOMATEX also supplies unperforated silicone sheets for pressing without steam at thermo printing, bonding, fusing, heat glueing, ...

The VOMAPOR silicone/foams are MADE IN GERMANY and offer great advantages because of the valued raw materials and the unique production method using ultrasound vibrations which distribute the silicone evenly through the PU-foam base. This technique prevents from the formation of air bubbles and improves the heat resistance and the durability of the foam. VOMAPOR extends the replacement interval and provides a constant ironing quality. It is not hazardous for the environment and thus protects the health of your workers and the consumers. VOMAPOR is available in many different hardnesses, colours and thicknesses.

Sometimes VOMAPOR is mixed up with the blue Poly-foam which is the standard padding for industrial vacuum ironing tables. Compared to other foams which are offered for the same purpose our Poly-foam has an extraordinary high cubic weight which makes it resistant towards pressure and a special reticulation treatment for a superior permeability. Poly-foam is not as heat resistant as VOMAPOR silicone/foam but it is an excellent pad for ironing tables.

We are looking forward to give you more information about our wide range of heat and pressure resistant high quality products.

Following qualities are available immediately from our huge stock in Bremen, Germany:

VOMAPOR silicone/foams

Made in Germany

VOMAPOR 100, lightred

Standard thicknesses: 5 mm, 10 mm, 15 mm

Length of rolls: abt. 10 meters

Width: 135 cm

Temperature resistance: up to 160°C

Purpose: Used as an extremely soft intermediate padding especially at ironing delicate clothing.

VOMAPOR 115, red

Standard thicknesses: 6 mm, 8 mm, 10 mm, 15 mm

Length of rolls: abt. 10 meters

Width: 135 cm

Temperature resistance: up to 170°C

Purpose: Used as a very soft intermediate padding especially at ironing delicate clothing.

VOMAPOR 30, yellow

Standard thicknesses: 3 mm, 6 mm, 8 mm, 10 mm, 15 mm

Length of rolls: abt. 10 meters

Width: 135 cm

Temperature resistance: up to 180°C

Purpose: Used as a soft intermediate padding

VOMAPOR blue - The industry standard

3 Qualities: supersoft, soft, hard

Standard thicknesses: 6 mm, 8 mm, 10 mm, (4 mm available in hard quality)

Length of rolls: abt. 10 meters

Width: 135 cm

Temperature resistance: up to 210°C

Purpose: Used as the standard intermediate padding. Very durable for constant ironing result.

VOMAPOR 275, turquoise

Standard thicknesses: 6 mm, 10 mm

Length of rolls: abt. 10 meters

Width: 135 cm

Temperature resistance: up to 220°C

Purpose: Used as a hard lower padding

VOMAPOR for trouser presses

(with central stripe)

The VOMAPOR silicone/foam with 60 mm wide supersoft central stripe is especially designed for trouser leg presses. At pressing the crease you often have problems with shine at the side seam. For this reason we developed VOMAPOR sheets with a supersoft central stripe allowing the double seam to sink into the supersoft area whilst the crease is pressed at the firm sides.

Because these sheets are being produced out of one single piece of foam there will be no marks at the transition between the supersoft central stripe and the firm sides.

Size of sheets: 1350 x 600 x 10 mm.

VAU-SIK foamed silicone ironing pads

Made in Germany

Type 8090, red

abt. 5 - 8° Shore A (very soft)

Type 8012, yellow

abt. 9 - 15° Shore A (Standard)

Special silicone pads

red, hard, 5 mm or 10 mm thick

red, medium, 4 mm, 6 mm or 10 mm thick

white, soft, 4 mm, 8 mm or 10 mm thick

Different thicknesses and hardnesses are available on request.

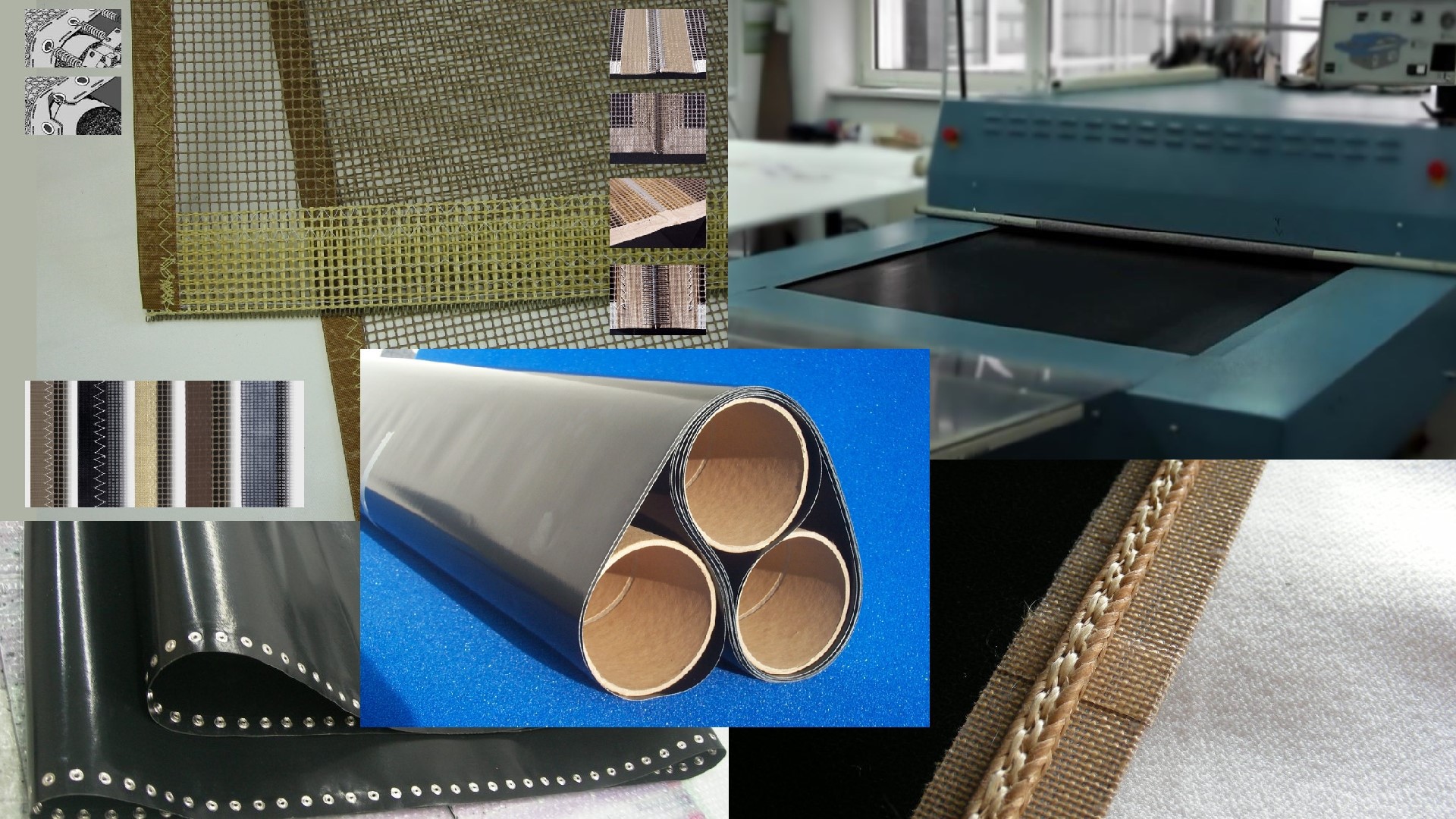

Heat Resistant Textiles

VOMATEX supplies a wide range of heat resistant high quality fabrics to the clothing industry and other branches worldwide. Most of VOMATEX textiles are commonly used as final covers on ironing tables and presses.

In the beginning of industrial ironing the machines were furnished with several cotton and wool fabrics. But due to its need for frequent changing and low heat resistance there is only one cotton blossom cover left in our range of products. It is mainly used on ironing tables at ironing bleeding clothing which requires frequent changes of the textile cover.

Cotton is almost totally being replaced by textiles made of artificial fibres like Polyester (e.g. Trevira®) and Polyamid (e.g. Nylon) which offer better physical properties and an excellent value for money. Since the demand for high temperature pressing and the need to extend the replacement interval became more relevant, factories are turning to even more heat resistant and durable textiles made of V-Max Aramid (e.g. Nomex®, Conex®) and PTFE (e.g. Teflon®).

The standard final cover for ironing velvet fabrics is the VOMAT bristle cover M III which is also available with a back of V-Max Aramid-needlefelt called VOMAT bristle cover M 300 NO making it more heat resistant and easy to fix on upper press plates.

The needle like Polyester bristles prevent from shine and give the desired rough finish to the clothing. The previous version VOMAT bristle cover M II has been invented by VOMATEX in 1972 and replaced the expensive metal needle plates. For shaped presses we recommend to use Nylon-Stretch as elastic final cover or the new heat resistant V-Max Aramid-Stretch.

Frames on presses especially on double leg trouser presses are furnished with Multi-Stretch. There are different qualities of Multi-Stretch available. If you do not know which type you require please send us a small sample and we will be glad to submit you an offer.

For fusing presses and other machines having sticky glue residue we offer silicone or PTFE coated fabrics which are glue repellent.

If you are looking for a heat resistant insulation fabric for your machines please take a look at our Thermo glass fabric with Aluminium coating.

Our big selection of fabrics contains also wire screen mesh which are used on ironing tables and presses to distribute the steam and improve the vacuum suction.

We are looking forward to give you more information about our wide range of heat and pressure resistant high quality products.

VOMATEX supplies immediately from stock heat resistant fabrics made of:

- Aramid (Nomex®, Conex®, ...)

- Para-Aramid (Kevlar®, ...)

- PTFE

- Glass

- metal wire screen mesh

- Polyester (Trevira®, ...)

- Polyamid (Nylon, ...)

- PEEK

on request coated with:

- silicone

- PTFE (Teflon®, ...)

- PU with aluminium pigments

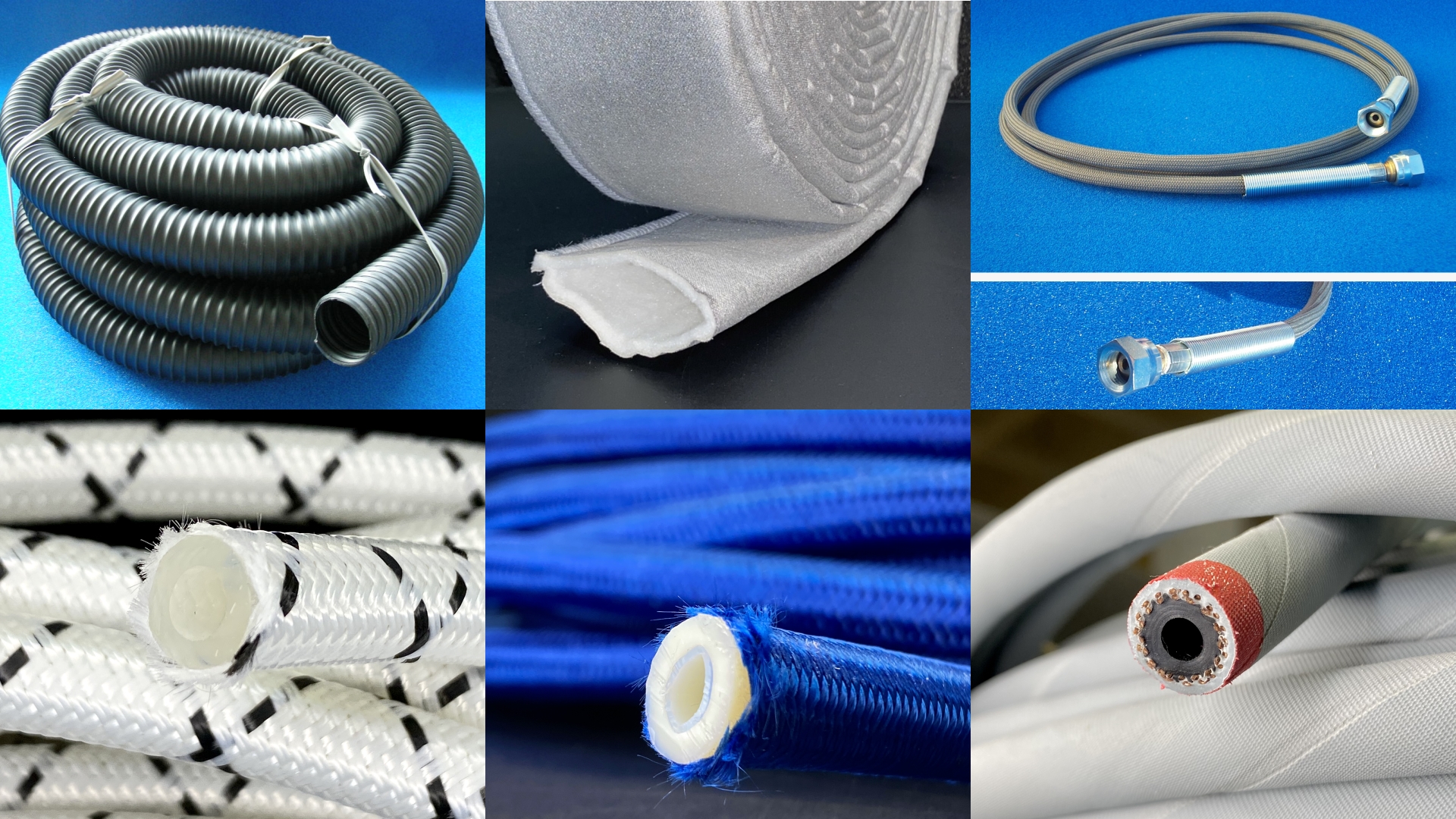

Steam Hoses - Vacuum Hoses

VOMATEX is supplying reliable high quality hoses to machine manufacturers and clothing factories worldwide.

There are two main groups of hoses: The vacuum suction hoses and the steam hoses. We are looking forward to give you more information about our wide range of heat and pressure resistant high quality products.

Vacuum suction hose

The standard vacuum suction hose is our durable and flexible GS hose which offers an excellent value for money. It was especially developed for the reliable suction of condensated steam.

Besides we supply the light and flexible A-P-A (Aluminium-Paper-Aluminium) which is not that durable.

Steam hoses

Steam hoses are classified in two grades: standard steam hoses and high pressure steam hoses.

The most advanced standard steam hose is the Teflon®/silicone multilayer steam hose VM 2.

This innovative product consists of three layers:

- Polyester braiding on the outside to prevent from injuries at skin contact.

- Silicone wall for flexibility and heat insulation.

- Teflon® wall with extremely smooth surface which avoids the condensation of steam.

Thus it prevents from water dripping out of the iron even after a short working break!

Other standard steam hoses are available with different inner diameters and wall thicknesses. They are manufactured with one or two silicone walls with a textile reinforcement inside or a braiding outside.

High pressure PTFE steam hoses are connected to the iron or the machine by screw caps.

Very flexible and lightweight high pressure hoses for connecting to irons usually have a 1/4“ screw cap.

PTFE hoses with stainless steel braiding are not that flexible but even more durable. They are used for connecting presses and tables to the steam supply. The lengths are custom made according to your needs usually with 3/8" or 1/2" screw caps.

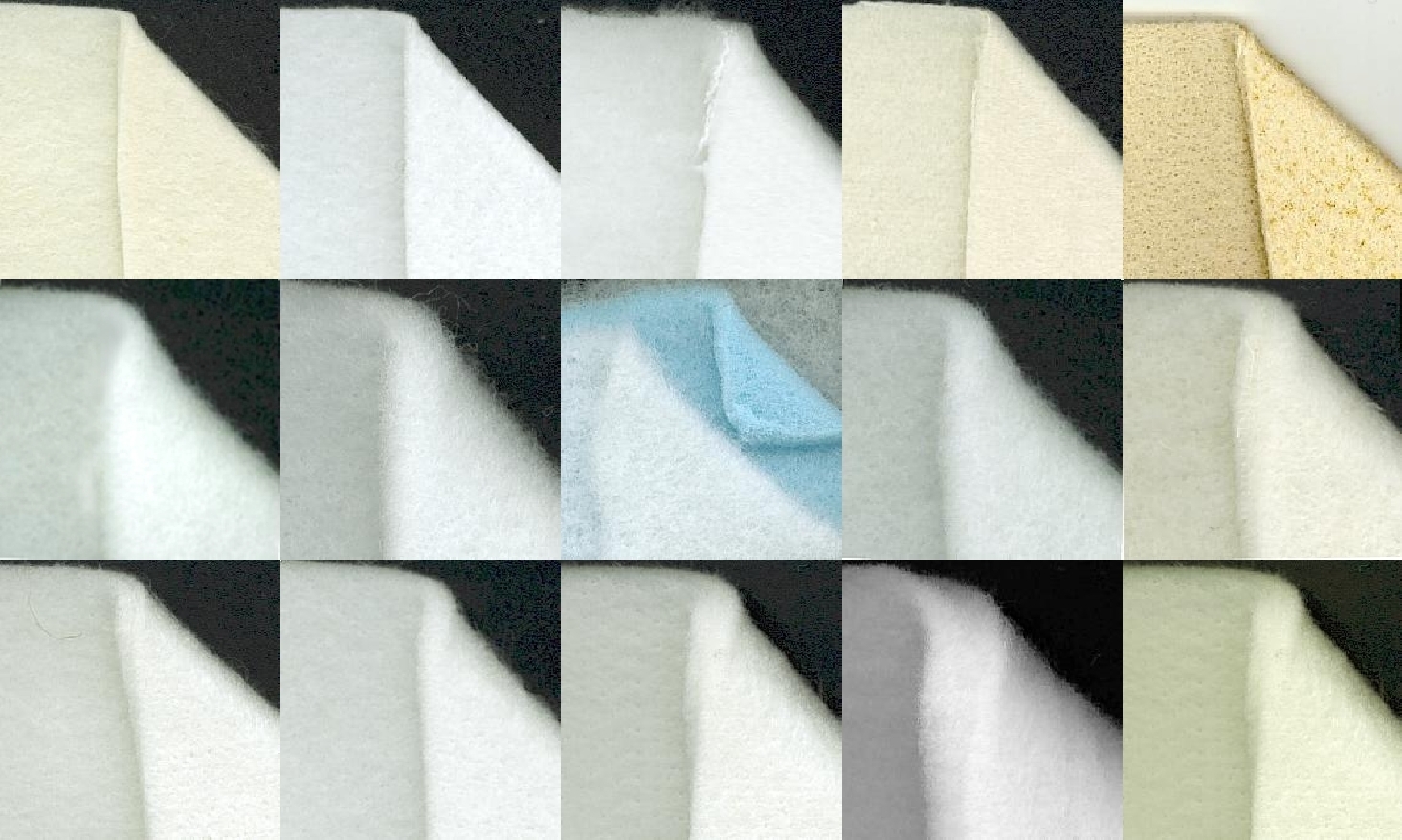

Aramid Felts - Polyester Felts

VOMATEX supplies a variety of high quality felts with different heat resistance, weight and thickness to the clothing industry and other branches worldwide.

On ironing machines the felts are used to spread the steam equally and to protect the clothing from spots caused by uneven steam distribution. Moreover our felts have a slight cushioning effect thus they help to avoid pressure marks.

Depending on the machine temperature you may use cotton or wool felts with low heat resistance or at the top of the range very heat resistant and durable V-Max Aramid felts.

The most commonly used felts are made of Polyester which offer a sufficient temperature resistance for most applications at a very competitive price.

Some felts have got a textile interlining making them more resistant to tension appearing on vertical presses or caused by the horizontal movement of irons on ironing tables. They are not suitable for shaped presses as they can not be formed well.

Besides some felts are used as inlets (e.g. at iron shoes) and for the cleaning of fusing machines.

We are looking forward to give you more information about our wide range of heat and pressure resistant high quality products.

V-Max Aramid-needlefelts

Due to the limited availability of orginal DuPont Nomex® Aramid fibres we can only ensure the continous production of felts which are containing Aramid fibres by using also Aramid fibres from different manufacturers.

V-Max Aramid is heat resistant up to 250°C / 480°F steam temperature.

V 209

Thickness: 4 mm

Length of rolls: 30 meters

Width: 160 cm or 180 cm

Purpose: Used on ironing tables and presses

V 216

firm felt

Thickness: 6 mm

Length of rolls: 30 meters

Width: 180 cm

Purpose: Used on ironing tables and presses.

V 218

Thickness: 6 mm and 8 mm

Length of rolls: 30 meters

Width: 160 cm

Purpose: Used on ironing tables and presses.

V 249

with interlining = tension resistant

Thickness: 5 mm

Length of rolls: 30 meters

Width: 160 cm

Purpose: Used on ironing tables especially at ironing wool fabrics (e.g. Cashmere coats).

Just put the garment directly upon the felt without any additional textile cover between them to preserve the natural look of the garment..

V 242

with interlining = tension resistant

Thickness: 2 mm

Length of rolls: 80 meters

Width: 235 cm

Purpose: Used on large ironing tables, steaming tables.and vertical presses.

Polyester-needlefelts

V 238

Thickness: 4 mm

Length of rolls: 30 meters

Width: 160 cm

Purpose: Used on ironing tables and presses.

V 201

Thickness: 6 mm

Length of rolls: 30 meters

Width: 140 cm

Purpose: Used on ironing tables and presses.

V 202

Thickness: 8 mm

Length of rolls: 30 meters

Width: 140 cm

Purpose: Used on ironing tables and presses.

V 2102

firm felt

Thickness: 10 mm

Length of rolls: 10 meters

Width: 140 cm

Purpose: Used on steaming tables.

V 264

firm felt, resistant to tension

Thickness: 1,8 mm

Length of rolls: ca. 50 meters

Width: 222 cm

Purpose: Used on fusing machines for cleaning.

V 260

Polyester-needlefelt with foam inlet

Thickness: 10 mm

Length of rolls: ca. 20 meters

Width: 140 cm

Purpose: Used as soft padding on ironing tables.

Cotton molton M 4

Napped cotton fabric

Thickness: 3 mm

Length of rolls: 30 meters

Width: 100 cm, 140 cm, 160 cm or 200 cm

Purpose: Used as an intermediate layer on ironing tables and on fusing machines as cleaning felt.

Wool needlefelt V 223

Thickness: 8 mm

Length of rolls: 30 meters

Width: abt. 200 cm

Purpose: Used on ironing tables as padding.

Wool felt

Thickness: 1.5 mm

Length of rolls: 30 meters

Width: abt. 190 cm

Purpose: Used on presses as dressing felt and on fusing machines as cleaning felt.

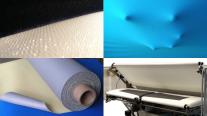

Transport belts

VOMATEX supplies different kinds of high quality transport belts e.g. for fusing machines, drying machines and shrinking machines. Almost every type of belt for these machines of the clothing industry can be supplied. We are looking forward to give you more information about our wide range of high quality products.

VOMATEX offers:

- endless woven belts made of PTFE coated fabrics

- endless welded belts made of PTFE coated fabrics

- open transport belts of PTFE coated fabrics which are exactly precutted pieces for self welding on the fusing machine

- conveyor belts from open mesh PTFE coated fabric (e.g. 4x4 mm or 2x2 mm mesh size)

We only produce custom made belts according to the dimensions and specifications you submit to us.

The majority of belts is produced for fusing machines. All these belts are available made of PTFE coated glass fabric and also many made of PTFE coated Kevlar® fabric which is more expensive but also more flexible.

Endless woven belts for fusing machines offer a unique tearing resistance and have no joint and thus no seam. Transport belts with seam usually show a bad heat transfer at the seam. Moreover a seam may cause different tensions inside the belt structure and thus can reduce its lifetime. All these problems can be avoided by using endless woven belts.

For welded belts there are several types of connections and connection angles available. By grinding the seam or producing an x-belt you can reduce the above mentioned problems to a minimum.

Of course the PTFE coated fabrics are also supplied by running meter. Some machines require a special belt guiding (e.g. aramid-guiding, Kevlar® guiding, silicone V-guiding or guiding with studs) which we can also attach if you submit us the dimensions for example with a technical drawing.

Unsere Ansprechpersonen

Marco Lopez

Export

Head of Division