The exhibitors & products at Texprocess 2026 will be available here from mid-January 2026.

SMS-200 MODULAR STRIP CUTTER

SMS-200 MODULAR STRIP CUTTER

Description

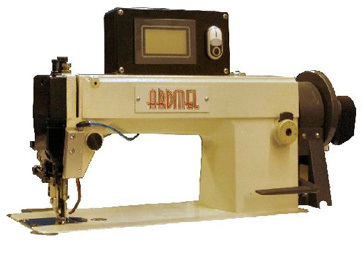

The Ardmel HMI Strip cutter is one of the most robust and reliable cutting system on the market today. The heavy duty unit is capable of handling the toughest of cutting tasks including industrial textile materials with extreme accuracy. The drive and control unit will accept any of the interchangeable cutting heads which are all pneumatically driven giving years of use with minimal maintenance.

Webbing, Seatbelts, Hook & loop, zippers, cords, ropes, tubing, tapes, industrial belting, elastic cords, ribbons, labels, felts, coated fabrics rubbers.

The 6” feed block is capable of multi feed. The top and bottom drive rollers are driven and spring clamped to avoid slippage. The motor has a “soft start” to prevent the fabric being pulled to hard at the beginning of the process thus reducing the risk of slippage or over stretching. With exceptional cutting accuracy within±1mm over a maximum length of 100mtrs. Feed speed is 36meters/Min with an inch speed for loading of 5mtrs/minute.

The machine is capable of cutting multi rolls at one time up to 6” wide. There is an option to go wider with our 9” cutting blade if required.

nput of data, e.g. Length, temperature etc. is entered through the HMI Panel which is designed for easy programming.

Optional attachments:

Heavy Duty Hot knife

Heavy Duty Cold guillotine knife

Angle Hot knife

Photo Detector

Slack Feed Unit

Mechanical End Detector