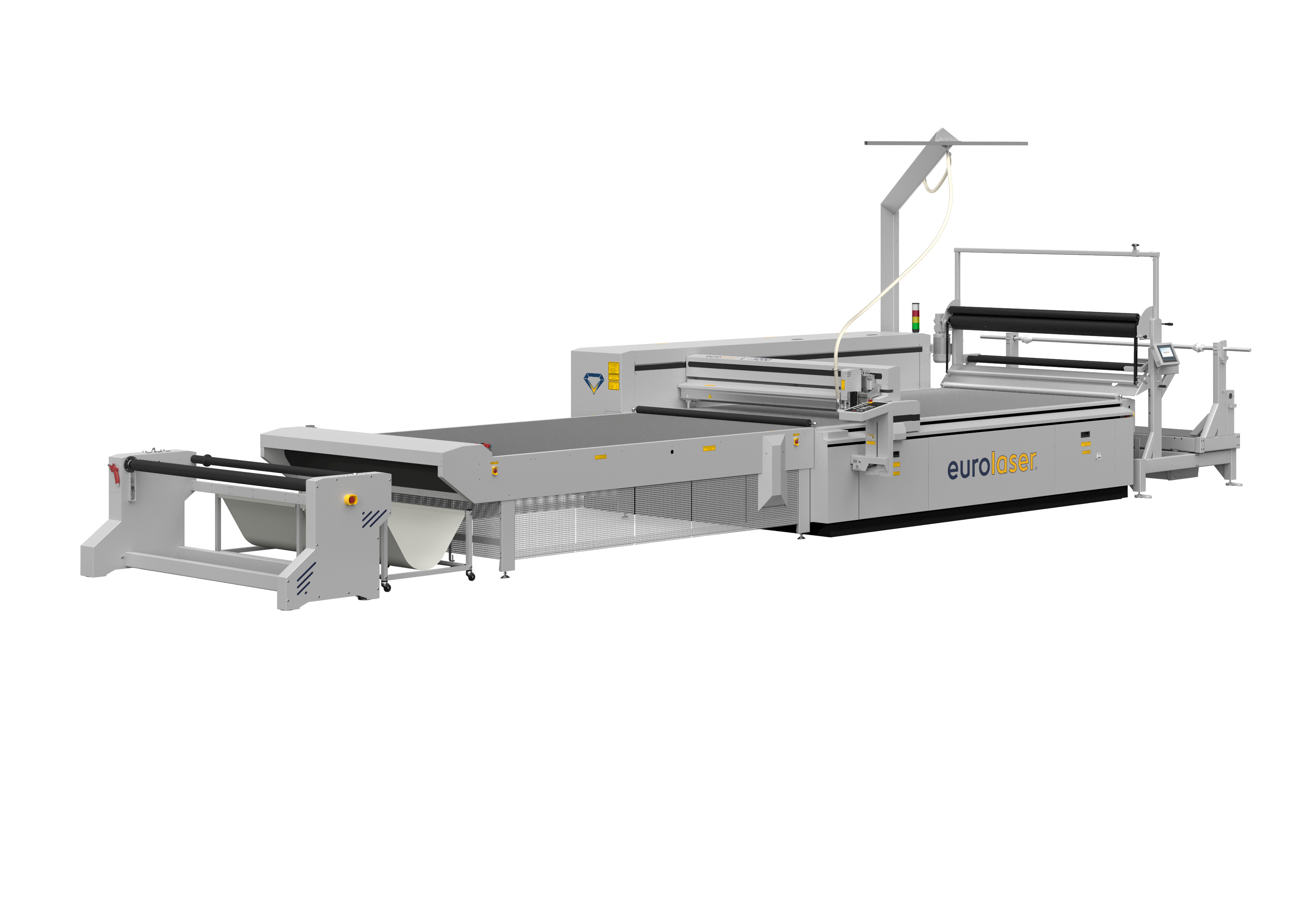

Laser Cutting System L-1200 with Conveyor System & Camera Recognition System

Laser Cutting System L-1200 with Conveyor System & Camera Recognition System

Description

NEW: Intelligent cutting of printed material

At this year's Texprocess, eurolaser is presenting a new camera system for the efficient and precise processing of printed materials. The new technology increases process speed and expands processing possibilities. The camera system will be presented on the laser system L-1200, on which printed textiles are automatically cut live.

Using reference points, the optical recognition system allows printed materials to be cut out precisely along the print contour. The new camera technology considerably reduces the time needed to read in the fiducial marks. The entire working area is quickly captured via area scan, thus optimising the process time. In addition, this process expands the range of possible applications. For example, contours on materials can be detected, whereupon suitable cutting data is created under software control. Pattern matching is also possible. Material patterns are detected so that the positioning of the cutting data is done taking the pattern into account. Useful functions that save time and money in further processing.

Laser Cutting System L-1200

- Working area (w x l): 1,800 mm x 1,230 mm (70.8" x 48.4")

- Laser power: 60-450 W

The laser cutting and engraving system L-1200 for textile processing offers unique precision and cut quality at highest cutting speeds, applicable to any material to be processed by individually choosing the right laser power. Your benefit: application-related efficiency.

Optional additions

- Conveyor system for automated processing directly from the roll

- Camera system for printed material, contour creation or pattern matching

- Label module for applying labels

- Ink printer module for printing

- Ink marker module for marking (e.g. sewing markings)

- Winding Unit for rewinding cut material

- and much more.

A special table concept is used for textile machining. This comprises a stainless steel wire mesh and is particularly suitable for thin and flexible materials. On the one hand, this is used as the material support for the machining process and, on the other, the transport element for the Conveyor System.

To put together the ideal laser system for your needs, we test your material in advance and then recommend the laser power, machining area and optional automation systems. You benefit from our expertise, acquired from over 10,000 successful application samples.