The exhibitors & products at Texprocess 2026 will be available here from mid-January 2026.

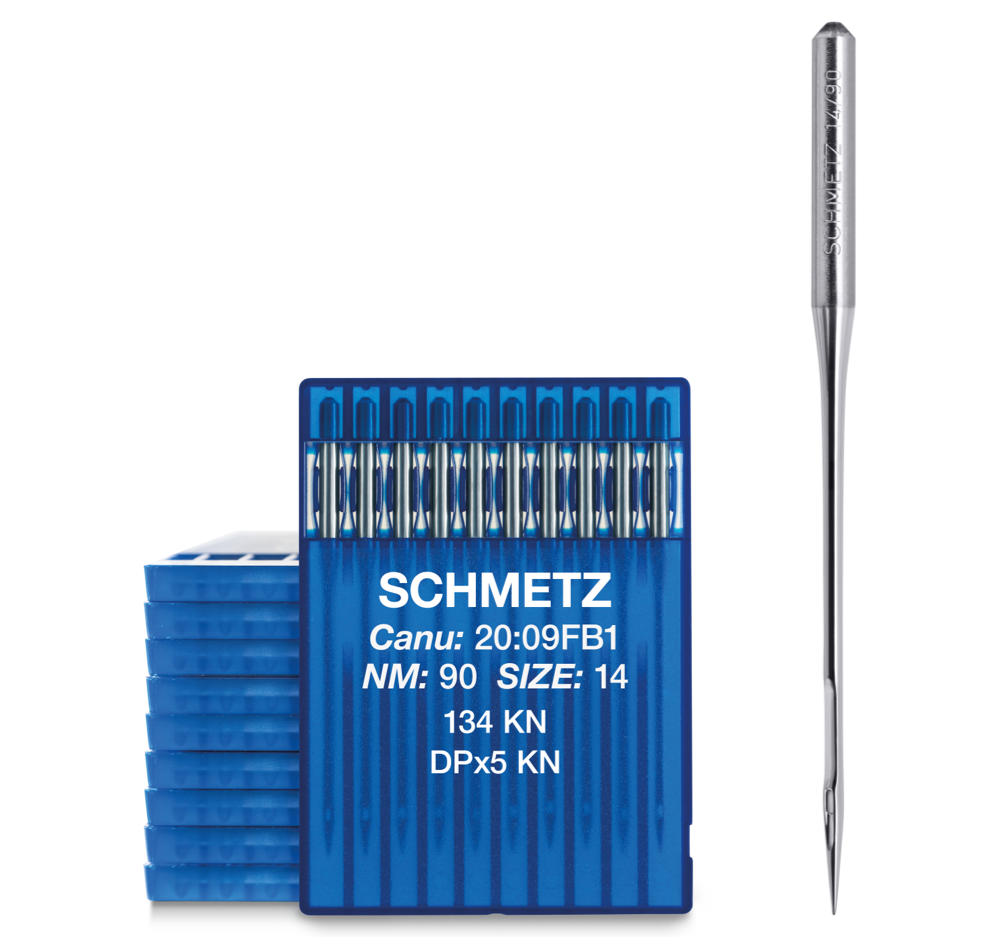

Ferd. Schmetz GmbH

Description

SCHMETZ GO Needles

Large eye area for heavy sewing threads

Usually, the needle size to be used is determined according to the sewing thread. However, sometimes it is necessary to sew with heavy sewing threads and it is not possible to match them to the corresponding needle size. For those cases, needles with GO design can help to avoid thread breakage and skip stitches and to achieve proper seams. The eye of GO needles is enlarged by 2 sizes in relation to the needle size, e.g. in a needle of size 70/10 the eye is of a needle size 90/14. Also the groove is enlarged.

Advantages:

- Thread guidance optimized by lowered friction, smooth passage of the sewing thread

- Minimization of damage to the sewing thread

- Reduced machine downtime

- Allows the use of thinner needles without changing the thread size

- Allows the use of a thicker sewing thread without changing the needle size

Application:

- Use of heavy threads or effect threads

- Decorative seams

- For achieving smaller stitch holes by using thinner needles, without getting thread problems

More from us

Our websiteMore products by Ferd. Schmetz GmbH

1 / 4