Mikkelsen Innovation ApS

About us

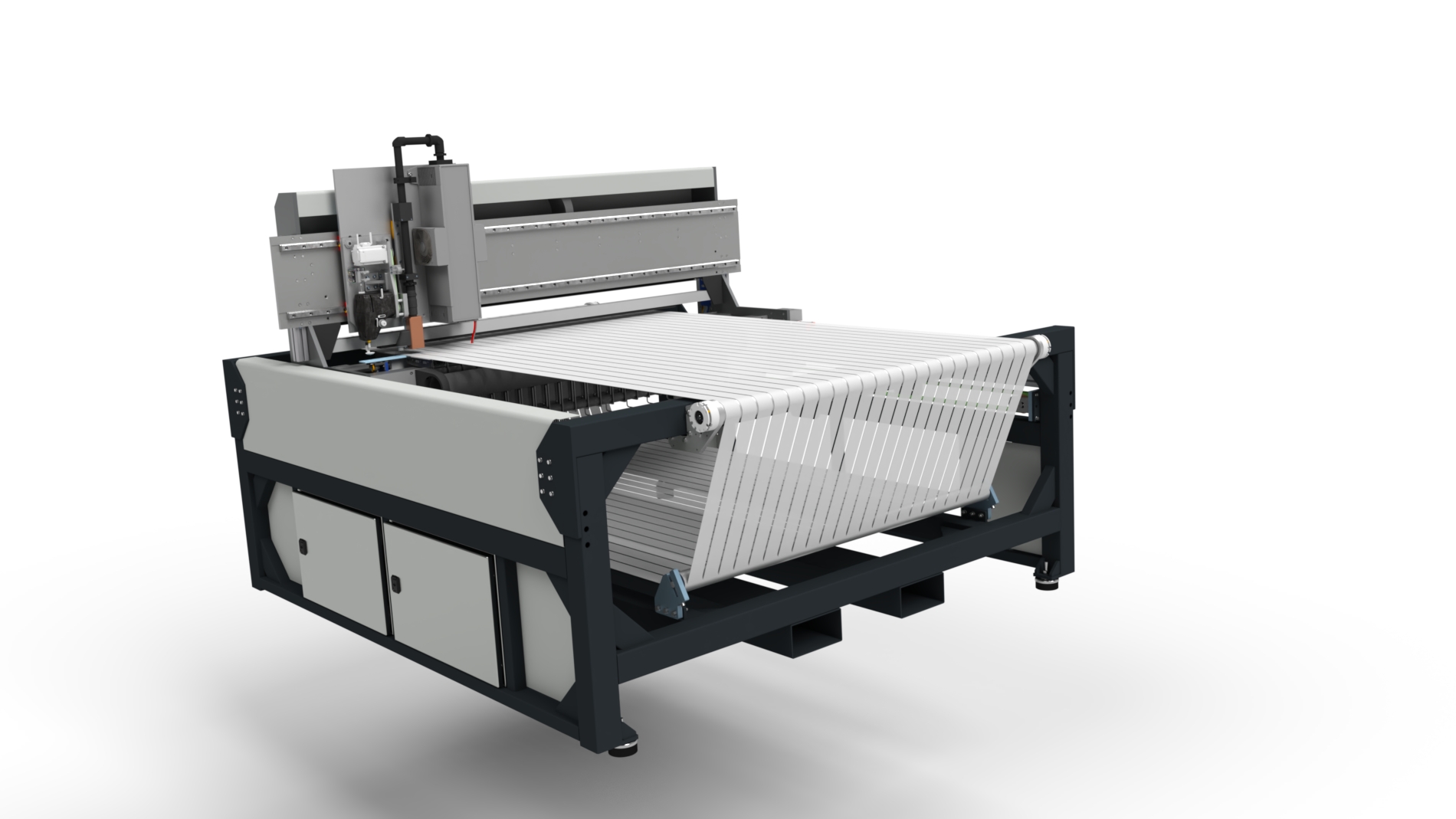

The textile industry has undergone significant digital transformation in design, printing, and cutting processes. However, sewing, a crucial manufacturing step, remains largely manual or semi-automated. FASTSEWN introduces patented technology that revolutionizes this final manufacturing stage. Two-dimensional textile products can be automatically conveyed into an integrated flatbed & cutting sewing system, allowing production of sewn goods in virtually any shape, including complex ones. The system uses a laser or knifetool, depending on textile type and product needs, for accurate cutting in relation to sewn stitches. At texprocess 2024, we will showcase a lockstitch sewing head and an integrated laser cutter at stand Stand A75, hall 9.

Initially targeting applications like automotive airbags, car seat and furniture tack-sewn parts, industrial filters, textile graphics, and ventilation airducts, FASTSEWN envisions broader applications. The technology facilitates automatic sewing and cutting from rolls without pre-cutting, reducing the need for frames and templates to be loaded and off-loaded manually. Its innovative movable conveyor cavity securely holds textiles in place during processing by use of vacuum system, enabling direct loading from rolls and offloading of the finished product.

FASTSEWN adapts to various table sizes (from 1 to 3 meters wide by 2 to 4 meters long) with a modular structure, delivering sewing and cutting tools per customer requirements. Steen Mikkelsen, with 25 years in CNC flatbed cutting technology, pioneered i-cut® vision solutions, acquired by larger competitors. Recognizing an opportunity for further flatbed CNC capability, FASTSEWN was born in 2021, earning a patent for its dual-sided processing technology to be showcased at texprocess 2024. The technology extends beyond sewing and cutting, proving useful in ultrasonic welding and cost-effective stand-alone laser cutting. FASTSEWN plans to license the technology, encouraging texprocess 2024 attendees to explore its potential applications.

Reflecting on the founders' journey, FASTSEWN originated from discussions about expanding flatbed CNC capability by allowing access to both sides of processed material. The first patent for this innovative technology has been issued, showcasing automated sewing, and cutting of multiple layers at texprocess 2024. Beyond textiles, the technology holds promise in other industries where two-sided processing is essential, such as ultrasonic welding.

The system's versatility extends to achieving a lower-cost stand-alone laser cutting capability, enabling roll feeding and more efficient fume extraction for automation at a lower cost for laser solutions. FASTSEWN plans to license this groundbreaking technology, providing a new platform for automation progress in various marketplaces. Additional patent-pending capabilities are under global review.

At the FASTSEWN stand at texprocess 2024, we invite attendees to join us in envisioning additional uses for this enabling technology. We welcome ideas for brand new applications and product ideas which will now be possible to create & produce efficiently. As we continue to innovate and expand the boundaries of automation, FASTSEWN aims to be a catalyst for transformative change across industries. Join us in dreaming and shaping the future of automated manufacturing. The FASTSEWN team is excited to join texprocess 2024 and demonstrate its system in operation.

Our product groups

- CMT (Cutting, Making, Trimming)

- Sewing Technologies and Materials

More about us

Special Interests

Keywords

- Sewing

- Cutting

- Automation

- CNC

- Textile