FASTSEWN Prototype 3

Description

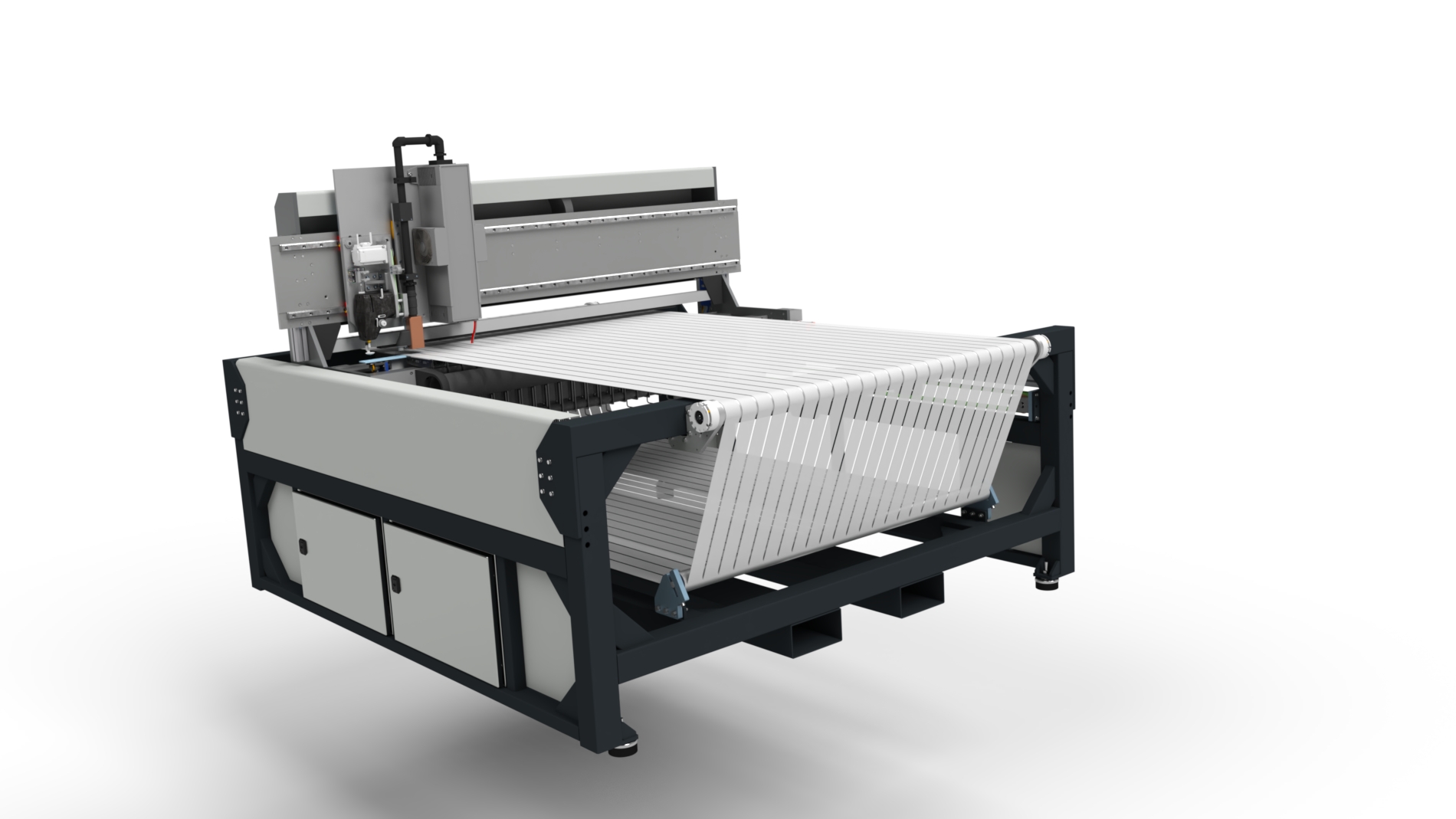

At TexProcess, a new company founded by automated flatbed cutting pioneer Steen Mikkelsen, along with an experienced team, has developed a new integrated sewing and cutting process. In this innovative patended technique, the traditional flatbed cutter conveyor belt is deviated to create a moving cavity in a flat surface with an enhanced vacuum system. Within this cavity, a bobbin moves in conjunction with the sewing head, enabling easy automation of sewn goods in virtually any 2D pattern. The process is futher automated with an integrated material transport system, and a vacuum hold down system, so the textiles can be sewn and cut directly from rolls to deliver a finished 2D sewn product.

This technology, known as Mobile Cavity Technology (MCT™), allows for the direct conveying of 2 or more layers of textile from rolls onto the processing table. The textiles can then be sewn and subsequently digitally cut by laser, knife, or rotary wheel, as required for the final product. MCT™ not only streamlines the manufacturing cycle by reducing manual handling but also elimiates the need for frames and provides further improvements in overall manufacturing efficiency with its size and shape versatility. In addition to the 10X improvement in sewing man hours, it also achieves a true 3 to 1 reduction in total handling through the combination of automated cutting with automated sewing.

On display on Texprocess 2024 will be a FASTSEWN automated Sewing and Laser Cutting System with a footprint of 2M X 2M and with a 1.2M Wide X 1.4M long working table bed and roll off/conveying from two rolls of 1.2M wide textile.

Stop by Hall 9, Stand A75 to see for yourself.

Discover more from us