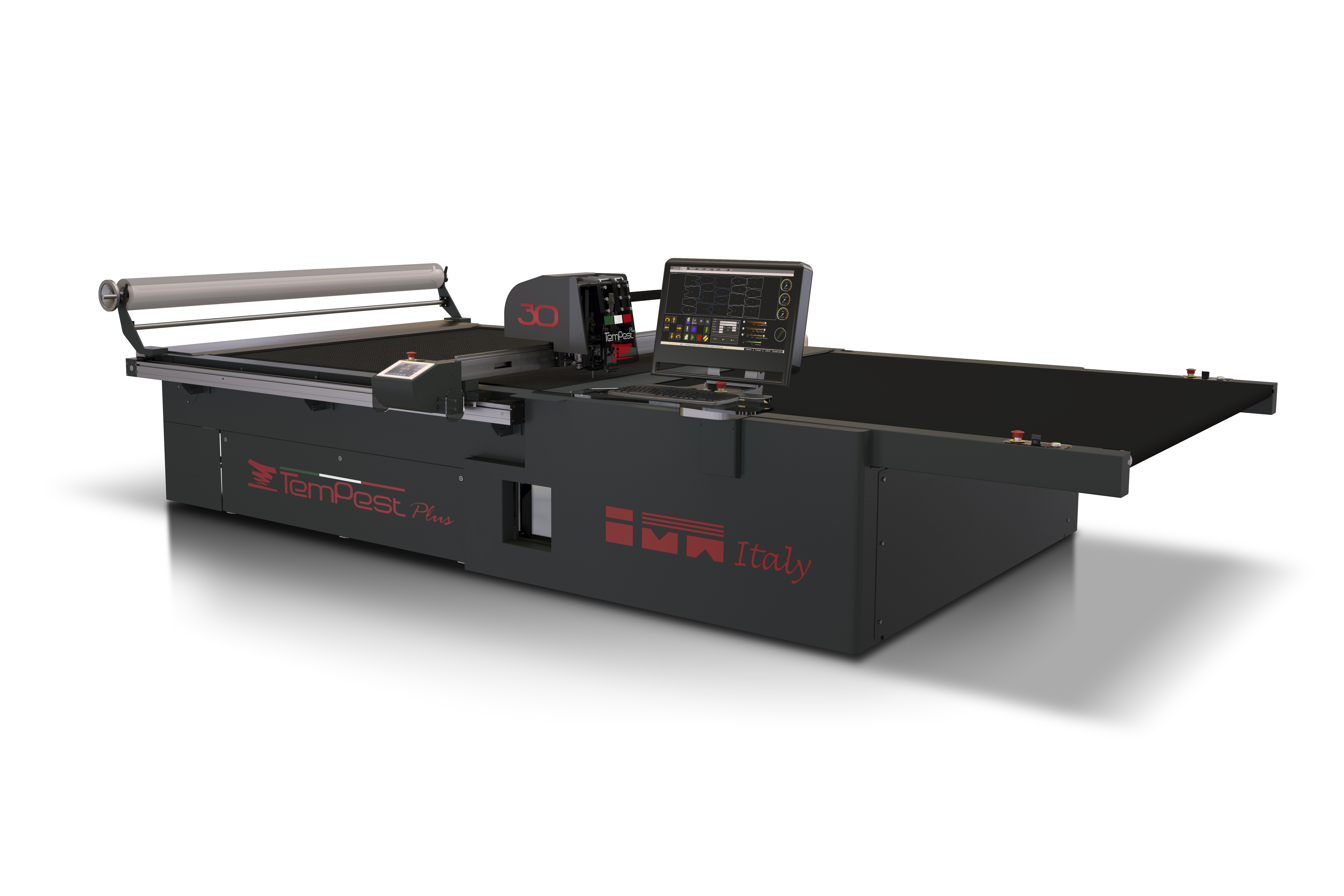

Tempest Plus 921.30

Beschreibung

Tempest Plus 30 - Automatic cutting machine for lays up to 30 mm compressed according to the type of fabric to cut. Structurally designed to achieve the highest level of performance and to reduce downtime during processing with high dynamic performances. The software of the machine is installed on a PC on board, increasing its efficiency and productivity, thanks to intuitive and flexible applications. Available as standard the possibility of storing an unlimited number of cutting profiles to be load if necessary. ntegrable for Industry 4.0 and IMA Syncro Cutting Room System. The innovative management of the vacuum system guarantees a reduction in consumption with the same performance. The digital technology totally based on the ETHERCAT communication protocol allows to check the status of the machinery in real time, with self-diagnosis functions and automatic options for adjusting the performance based on the type of work in progress.

Among the most important innovations we find gantry management of the bridge movement, management of differentiated pressure of the utilities most involved in the cutting process, touch screen placed on the bridge to allow the operator greater ease of intervention, Equipped with an inverter on all the utilities, an eco-friendly management of each motorization is ensured.

TECHNICAL FEATURES:

- Cutting window length: 175 cm.

- Cutting height: from single lay up to 30 mm of compressed fabric

- Installed power: 22 kw

- Power consumption: 6 kw

- Temperature from 10 ° to 60 °.

- Umidity from 30% to 80% without condensation.

- Voltage 400 V 3 PH 50/60 Hz.

- Weight: ~ 2500 /2700 kg

SOFTWARE SPECIFICATIONS

The software has been re-adapted in its layout and in supporting the

new mechanical features introduced.

- HMI (Human Machine Interface) sistem, designed by IMA. Very easy

and intuitive build on a color touch screen.

- Possibility to transform the polygonal system to the cartesian

geometry system, for better movements thanks to the optimization of

ISO cutting file.

- Adaptive movements functions of the machine while performing

curves or critical angles, then use zero buffer on marker..

- Possibility to manage symmetries of all patterns.

- Possibility to recognize and manage common lines.

- Automatic research of the starting point of the pattern.

- Possibility to change the cutting direction of the pattern.

- Different strategy of cutting for windows management, adjustable

according to every kind of fabric and marker, with cutting path optimization.

- Possibility to manage, convert and transform all kind of notches

(normal, V notch and fly notch).

- Possibility of merging different markers, to delete a single pattern

inside the marker and to manually move the pieces with a collision

control to optimize the workflow.

- Possibility of markers elaboration with graphic and statistic reports.

- Possibility to create and print a HPGL file for plotters from ISO file.

HARDWARE SPECIFICATIONS

- HMI software for machine management and CAM for cutting file

processing are pre-installed on the PC supplied as standard.

Windows 10 as operating system.

- Controlled vacuum by means of PID and double inverter

simultane-ously controlled, optimizing the power consumption.

- Mitsubishi command technology of engines of the latest

generation.

- Conveyor belt of loading and unloading perfectly synchronized

with the automatic cutting machine.

- Blade strainers, to increase the cutting quality.

- Blade speed up to 4000 rpm.

- Gantry ax for the movement of the bridge, increasing its ability of

control and precision as well as perfor-mance.

- Touch screen on the side of the bridge to easily manage the

machine even away from the PC.

Adresse

IMA S.p.A.

Via Piantada 9/A

25036 Palazzolo Sull'Oglio Brescia

Italien

Telefon+39 030 648 5011

Fax+39 030 648 5099

Entdecken Sie mehr von uns