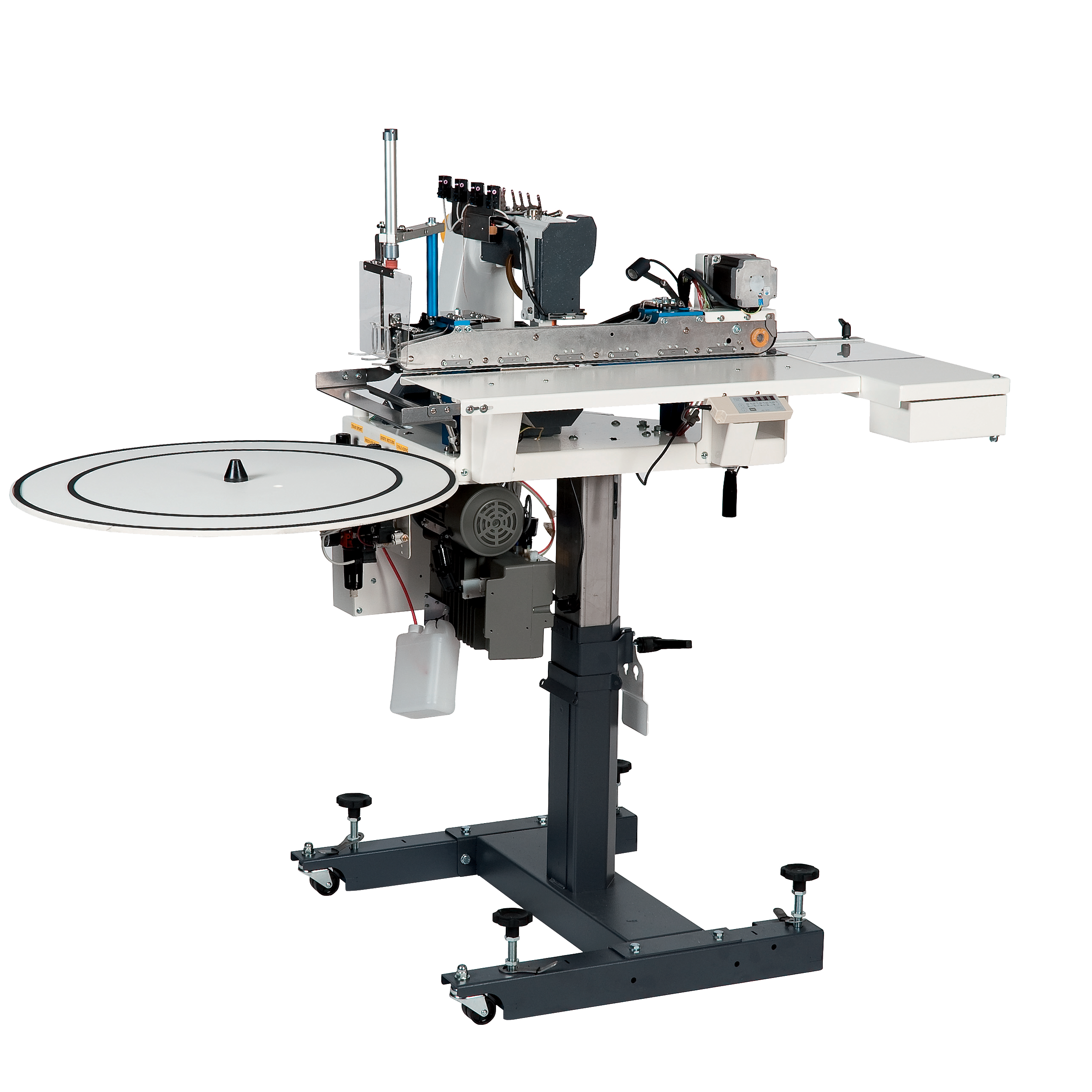

V3022BHE - Bottom hemming unit chain stitch or lockstitch

V3022BHE - Bottom hemming unit chain stitch or lockstitch

Beschreibung

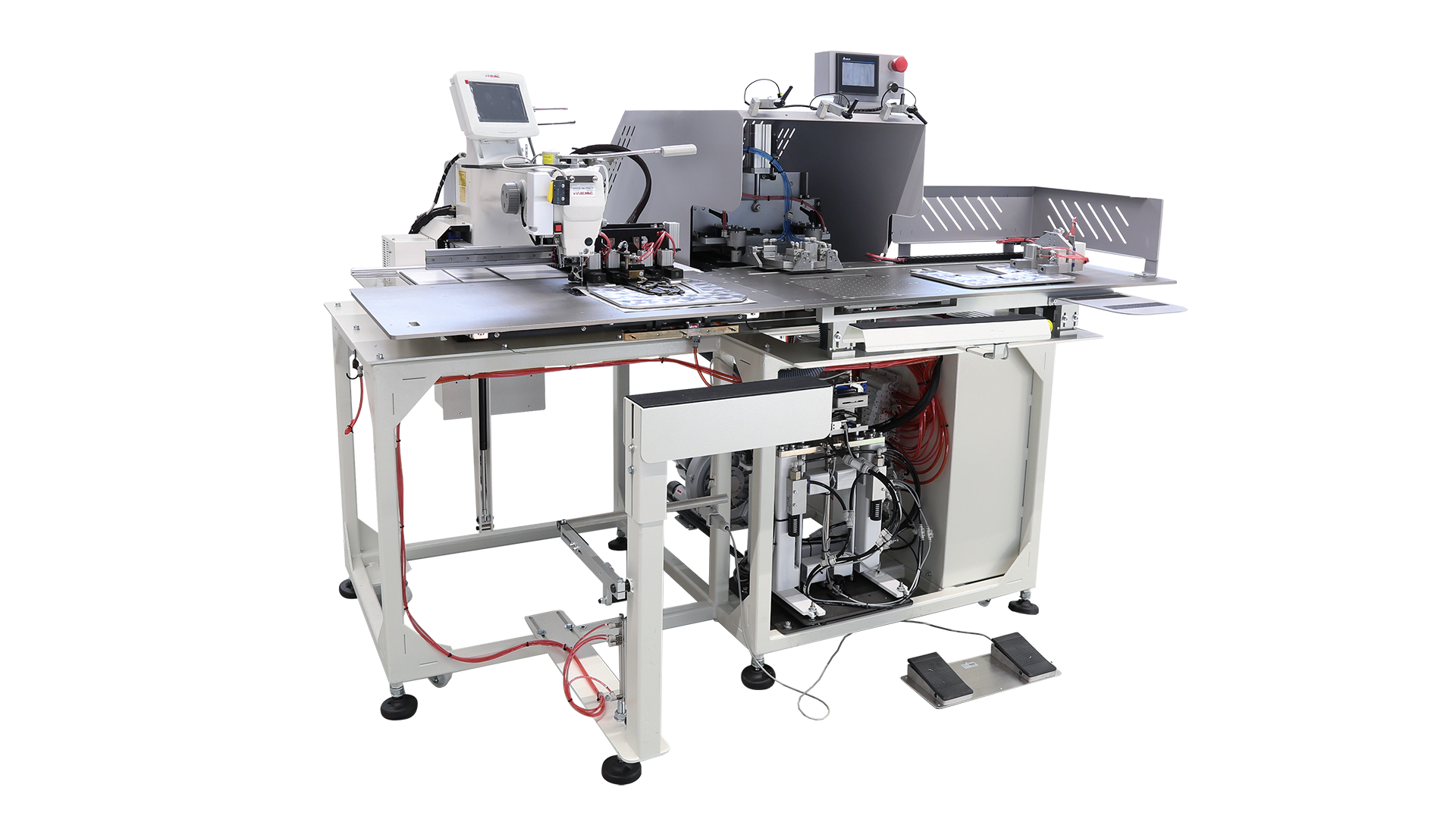

Benchmark in Vi.Be.Mac. product’s line (the world famous unit), this unit is entirely designed and manufactured in its own factory. The V3022BHE represents the markets solution to trouser hemline problems: accurate, productive and characterized by the flexibility that has become the hallmark of all Vi.Be.Mac. products.

Adjustable front and reverse folders, with a high standard efficiency, especially in terms of flexibility thanks to the fast conversion kit able to change from chain stitch to lockstitch and vice-versa in approx 25 minutes.

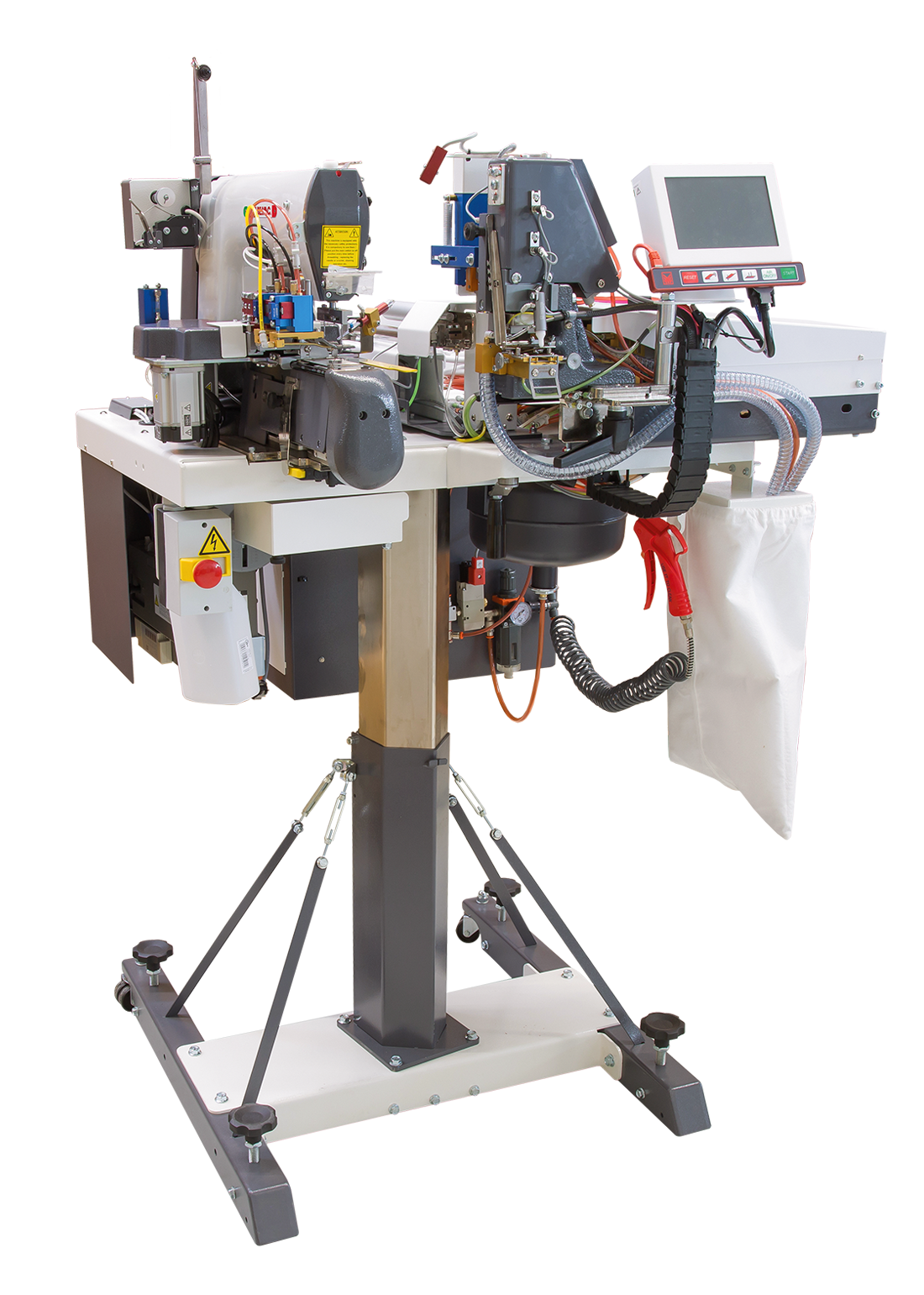

» Fast conversion (patented)

Thanks to the fast conversion kit the unit can be converted in less than 25 minutes from lockstitch to chain stitch and vice-versa

» Needle feeding technology

Able to perform on the most difficult stretch fabrics, always granting a high quality result

» King size hook system

Thanks to the king size hook the bobbin changes are reduced drastically with higher productivity

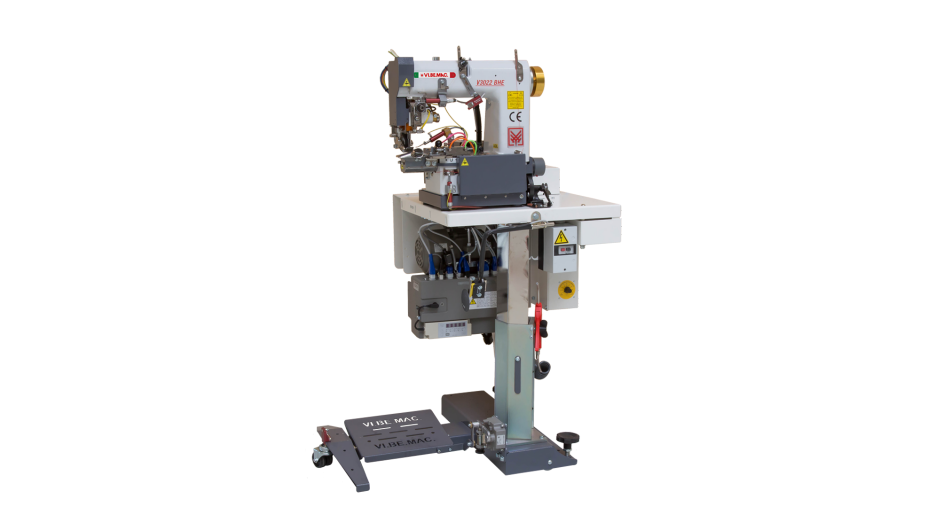

TECHNICAL SPECIFICATION

- Max Sewing Machine Speed: 4000 rpm chain stitch, 3500 rpm lockstitch

- Standard Stitch Length: from 0.9 to 5 mm (optional till 9 mm)

- Hem Width: from 9 to 30 mm (optional 42 mm)

- Sewing Head: Vi.Be.Mac.

- Sewing Machine Motor: Juki XCG 554 20Y - 550 W

- Control Box: XCG MFY 2005

- Power Supply Voltage: 220 V 50/60 Hz

- Air Consumption: 2 L/min

FEATURES

- Condensed stitch for closing: on the chain stitch style hemming operation it’s possible to close the stitches with a condense stitch, avoiding the need of another operation step

- Two needle plates with thread trimmer: for chain stitch and lockstitch

- Change from light to heavy fabrics: made without any alteration to mechanical components or electronic adjustments

- Pneumatic system for the toggle-joint opening of the guide: it can be selected by the operator in two different modes, manual or automatic, with the foot lifting at the same time

- Pneumatic foot lift

- Electronic stitch length can be set up easily with the electronic panel, for the maximum flexibility and operator’s comfort

- Front and reverse adjustable folders

- New design of the stand: easy adjustment in height

OPTIONAL

- Increased hem width: 42 mm