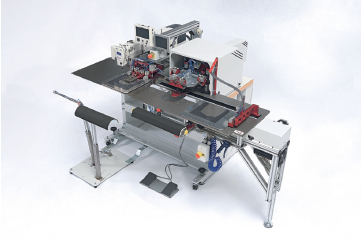

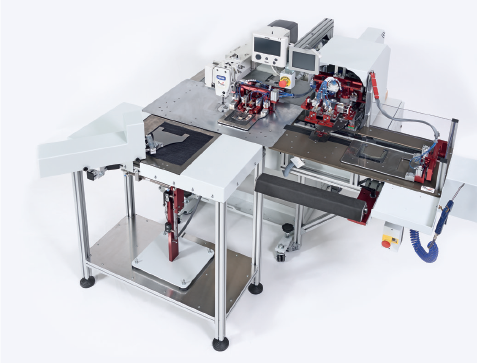

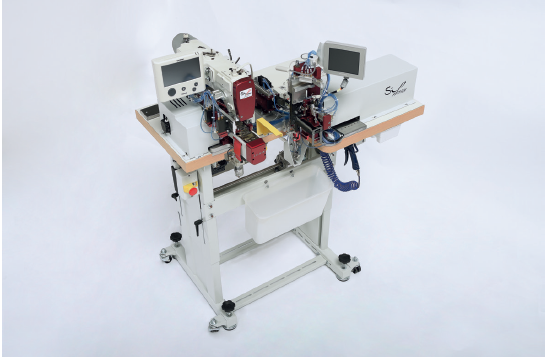

CP341-FG-SIP

Description

FULLY AUTOMATIC PROGRAMMABLE UNIT FOR COIN POCKET AND FACING ATTACHING OPERATION - EQUIPPED WITH COLD FOLDING GROUP

Automatic workstation for coin pocket and clean lock stitch facing attaching operation.

The same unit can be utilized as standard back pocket attaching operation for kids wear garment.

HIGHLIGTHS

- Clean lock stitch of the facing: new “must” for premium brand, value added style product at lower production cost!

- Fashion watch-coin sewing programme;

- Folding and attaching on the same workstation;

- Cold folding device is the unique solution for stretch denim fabric;

- Original Brother sewing head, standard X-Y technology, hardware & software by Brother Japan, same as other Brother units;

- No extra workers and helpers to manage the Coin pocket and facing operations: instead of marking, folding and different sewing stations, everything is made in one workstation;

- Digital sewing thread tension;

- Presser foot height controlled by step motor, editing sewing programme;

- Local pocket jig production by user in all countries of the world;

- Automatic device for quick pocket jig change;

- Friendly use, no skill operator and helpers required;

- LED lights for panel positioning;

- Multicolor touch screen 5.6” programmed for multi languages;

- All standard pneumatic valves and cylinders by SMC;

- Lowest running cost. Freedom to outsource the standard consumable spare part in all market locally at the best price and delivery.

PRODUCTIVITY

Coin pocket operation with 80% efficiency:

360 pcs / 1 working hour

8 seconds / cycle

Left and right facing operations

with 80% efficiency:

265 pairs / 1 working hour

6 seconds / cycle

Coin pocket, left and right facing operations:

120 pairs / 1 working hour

1.000 pairs / 8 working hours

TECHNICAL DATA

Min and Max coin pocket finished size:

from 60 x 60 mm to 120 x 120 mm

Min and Max facing finished size:

from 60 x 60 mm to 195 x 160 mm

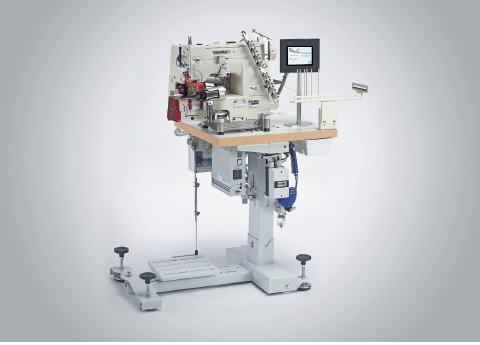

Sewing head utilized:

Brother model BAS-341 H serie,

NEXIO Technology, single needle lock stitch, direct drive, eco energy product

Max sewing speed:

2.800 rpm

up to the stitch length of 3.5 mm

Power supply and air consumption:

220 Volt, mono-phase 50/60 Hz

1.0 Kw

30 liters/cycle at a pressure of 5.5 bar

Size and weight of the workstation:

145 x 191 x 203 cm – 400 Kg

OPTIONS

- PS-300B Sewing data programming software by Brother for creating, editing, setting and converting of sewing data;

- IoT Software for FACTORY 4.0 network connectivity by Brother.

Address

Sip-Italy S.r.l. Società Benefit

Via Maestri Del Lavoro 12

37059 Zevio Verona

Italy

Telephone+39 045 1117 0246

Fax+39 045 605 1645

Discover more from us